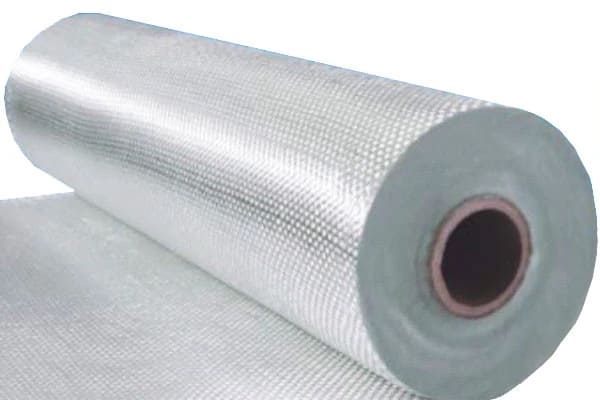

Glass fiber is used as reinforcement in fiberglass, and the glass fiber is then flattened into a sheet. Other names for it include glass-reinforced plastic and glass fiber-reinforced plastic. Read More…

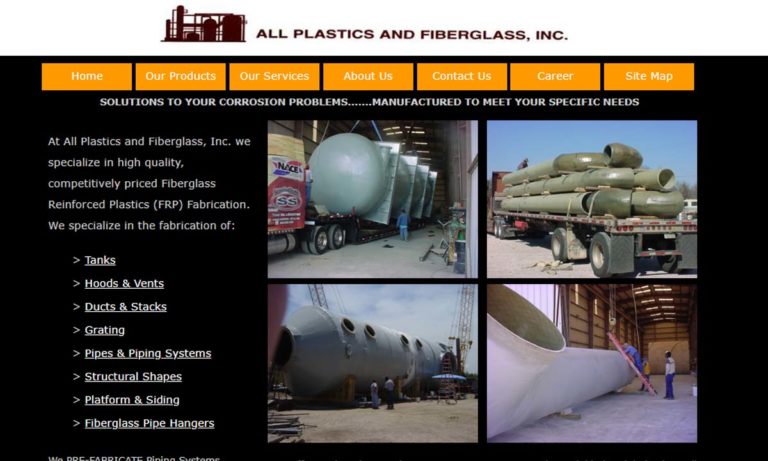

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

CT Composites offers a variety of fiberglass fabrication capabilities, including open molding, closed molding, repair, coating, and refurbishing. They specialize in commercial shrink wrapping, vacuum infusion processing, and light resin transfer molding. With experience providing solutions for industrial, residential, and federal industries, CT Composites offers high-quality service and results.

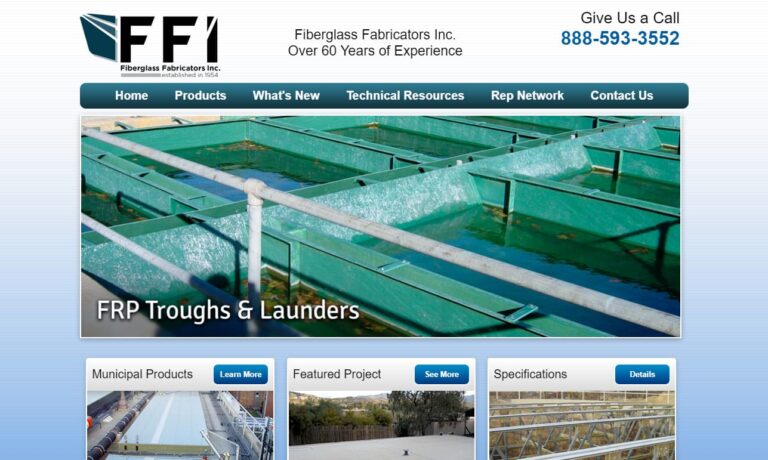

We are a premier manufacturer of fiberglass products. We take pride in our ability to custom build any type of solution that our customers may request. Our teams are the experts of the fiberglass fabrication industry. Turn to us for reliable and consistent products. All of our fiberglass items are reinforced with the best materials. Please give us a call today to learn more.

Fiberglass Innovations LLC provides custom fiberglass fabrication and manufacturing services. They specialize in precision-crafted tool handles and FRP composite rescue tools. Fiberglass Innovations LLC also designs custom fiberglass products. Their capabilities include cutting, sanding, painting, assembly, and crating. Experience the future of fiberglass with Fiberglass Innovations LLC.

More Fiberglass Sheet Companies

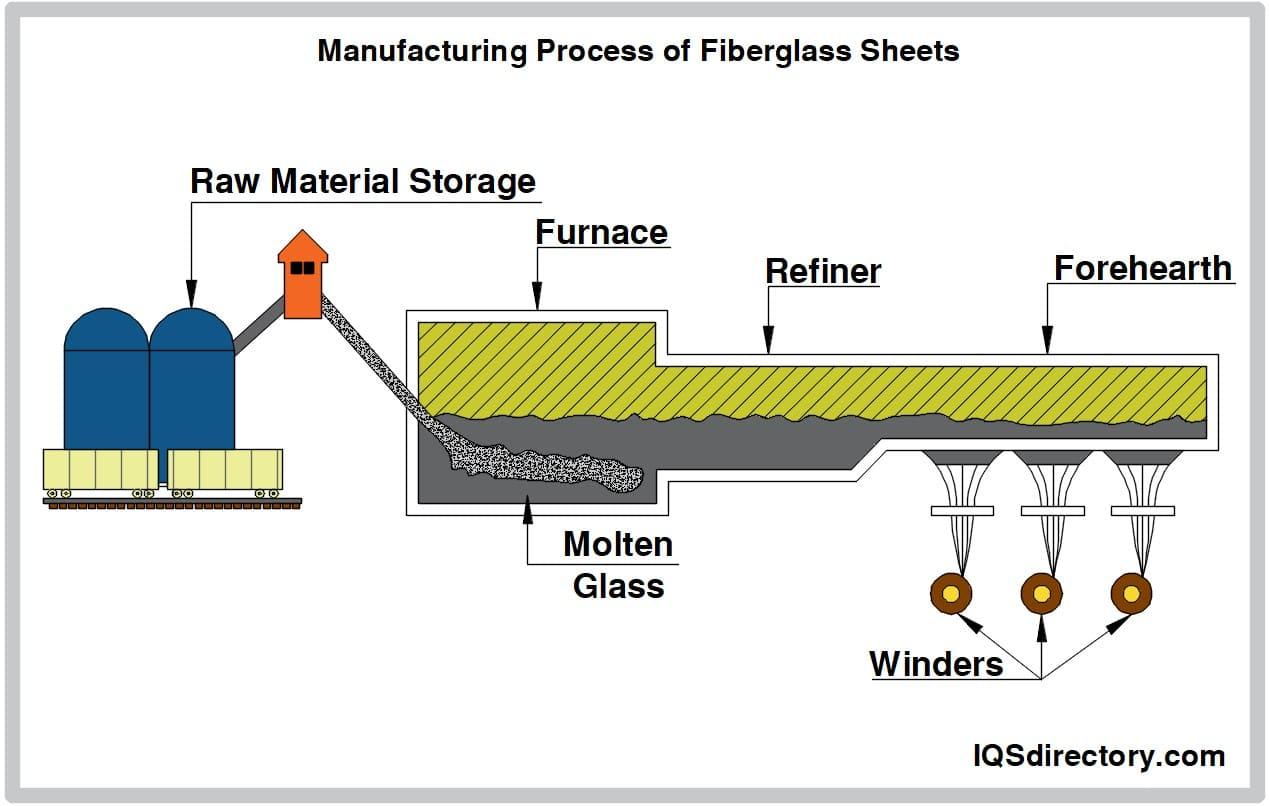

How Fiberglass Sheets are Manufactured

Fiberglass is made by heating raw ingredients together in a furnace. Ingredients may include silica, sand, limestone, kaolin clay, and dolomite. Batching is the process of weighing, measuring, and preparing the ingredients for the furnace. Manufacturers can automate the batching process.

After batching, the ingredients are heated to their melting points in a furnace. The furnace is built with enough space for the molten glass to flow into a refiner, where the glass is allowed to cool.

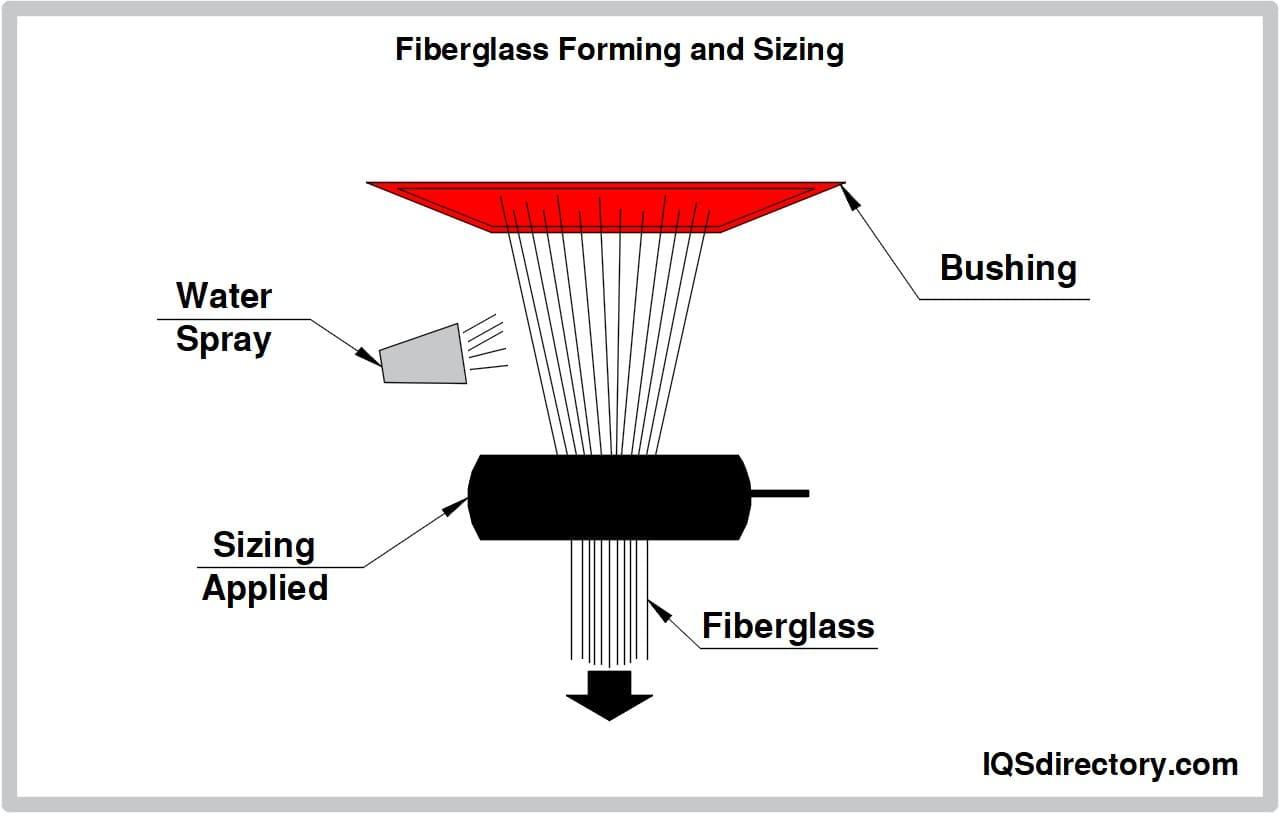

The last section of the furnace has bushings underneath that extrude the heated glass. The heated glass is extruded through extremely small brushes or spinnerets to create filaments. As the heated glass streams through the bushings, water jets cool the glass to keep its shape. The filaments are chemically finished and coated, then bundled together in a group called a roving. The weight of the glass fibers is measured in a unit called a ‘yield’. Yield is determined by the quantity, density, and thickness of the filaments in a roving.

The streams of extruded molten glass are mechanically pulled into filaments through attenuation. A high-speed winder catches the molten streams, and as it spins rapidly, strain is produced, drawing the streams into thin filaments. Depending on the type of fiber, several various procedures are employed, the two main types being the continuous filament and the staple fiber methods.

Types of Fiberglass

A-Glass Fiberglass

A-glass is chemically resistant and called alkali glass or soda-lime glass. It is the most prevalent form of fiberglass used to produce window panes, glass jars, and bottles. A-glass is affordable, hard, and chemically stable. A-glass is ideal for recycling because it can be remelted and softened.

C-Glass Fiberglass

C-glass (also known as chemical glass) is incredibly resistant to chemical impact. When exposed to corrosive conditions, C-glass maintains structural equilibrium. C-glass has large amounts of calcium borosilicate to help ensure that stability. Chemicals used to produce C-glass have pH values that offer high resilience in alkaline or acidic environments. C-glass is often used as a surface tissue in the outer layer of chemical tanks and pipes.

E-Glass Fiberglass

E-glass, commonly referred to as electrical glass, offers effective electrical insulating qualities. E-glass cannot be used for marine applications because it’s chloride-ion sensitive. It is a lightweight composite material with industrial and aerospace applications. Although E-glass was initially created for electrical applications, it is currently used in many other contexts.

Additionally, glass-reinforced plastic can be produced using a mixture of thermosetting resins. The panels and sheets made from glass-reinforced plastic are used in various industries to help maintain structural integrity.

Applications of Fiberglass

- Fiberglass is ideal for electrical applications because of its high mechanical strength and thermal stability. Fiberglass coatings are used to insulate wiring. Transformers, distribution-pole hardware, computer parts, and smartphone components all have fiberglass. Due to its non-conductive nature, fiberglass is also used in the power generation industry.

- Consumer goods like furniture frames, divider screens, decorative trays, wall plaques, sporting goods, playground equipment, etc., can all be made from fiberglass in consumer goods. Because of its increased strength, less weight, formability, durability, and resistance to wear and corrosion, fiberglass is the main material in numerous consumer items.

Choosing the Correct Fiberglass Sheet Supplier

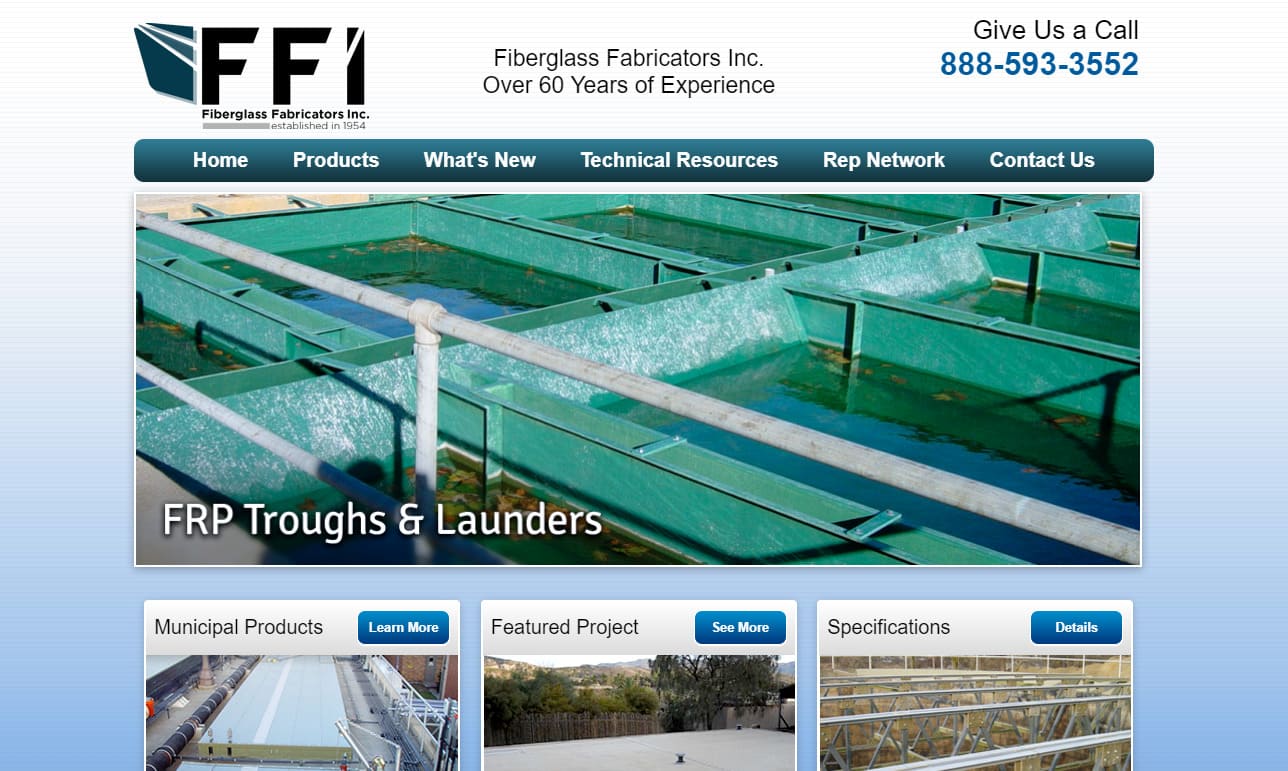

To ensure the most constructive outcome when purchasing fiberglass sheets from a fiberglass sheet supplier, it is important to compare several companies using our directory of fiberglass sheet suppliers. Each fiberglass sheet supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each fiberglass sheet business website using our patented website previewer to quickly learn what each business specializes in, Then, use our simple RFQ form to contact multiple fiberglass sheet companies with the same form.

Fiberglass Fabricators

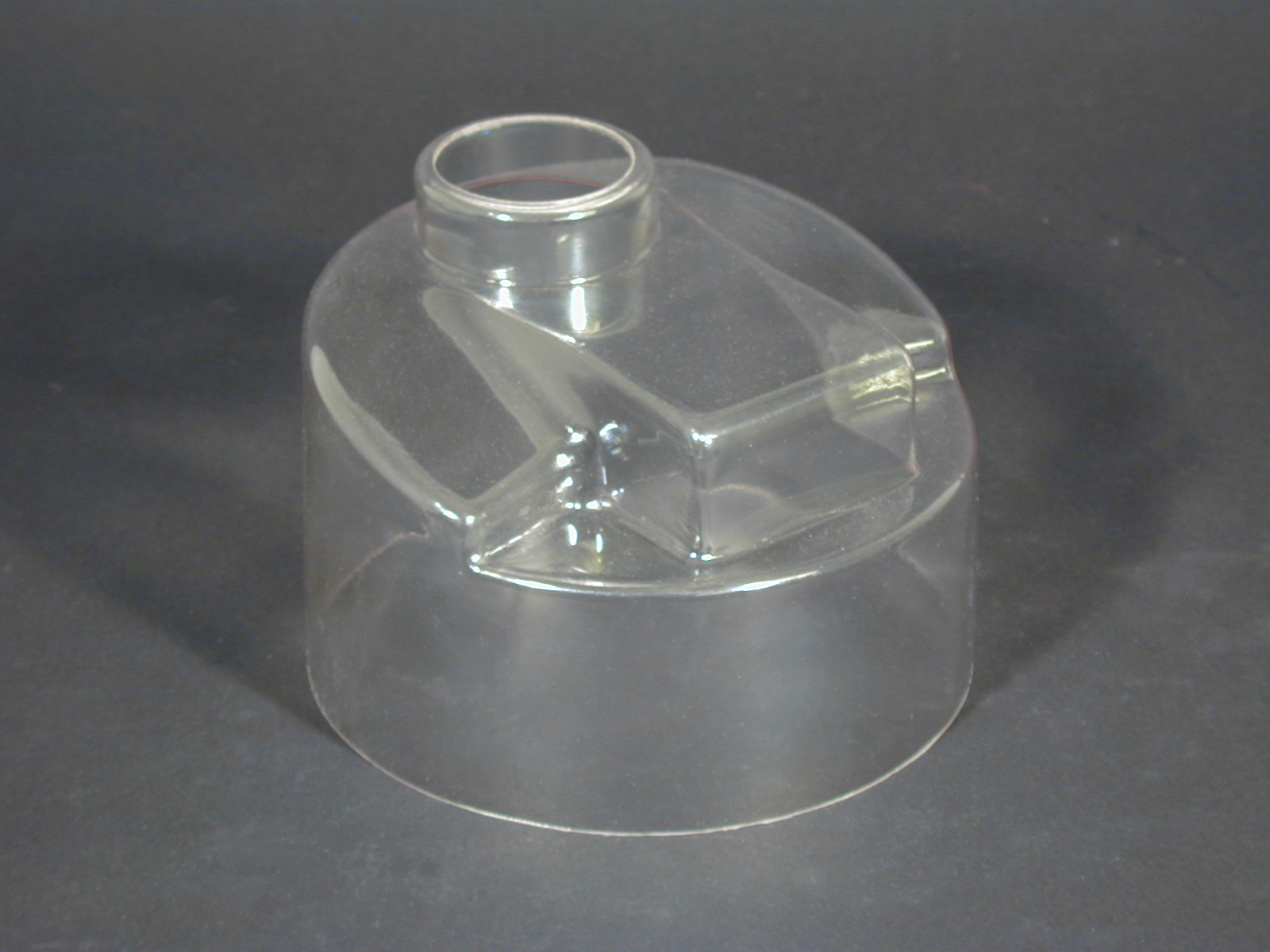

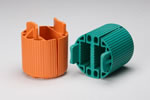

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services