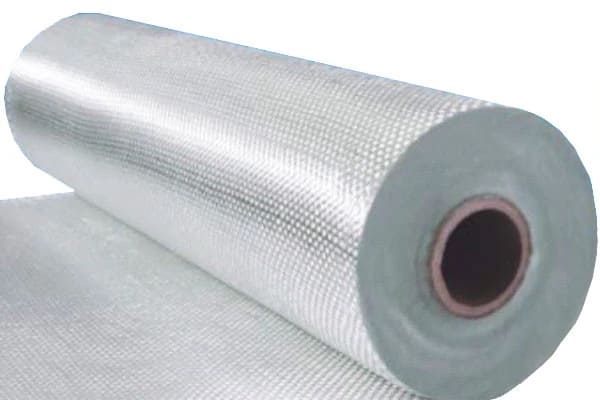

Fiberglass fabrication is a versatile manufacturing process that involves shaping and molding fiberglass materials to create various products. Fiberglass, also known as glass-reinforced plastic (GRP), consists of fine fibers of glass embedded in a polymer matrix. This combination results in a lightweight yet durable material that finds widespread application across multiple industries. From construction to transportation, fiberglass fabrication has become an integral part of modern manufacturing processes.Read More…

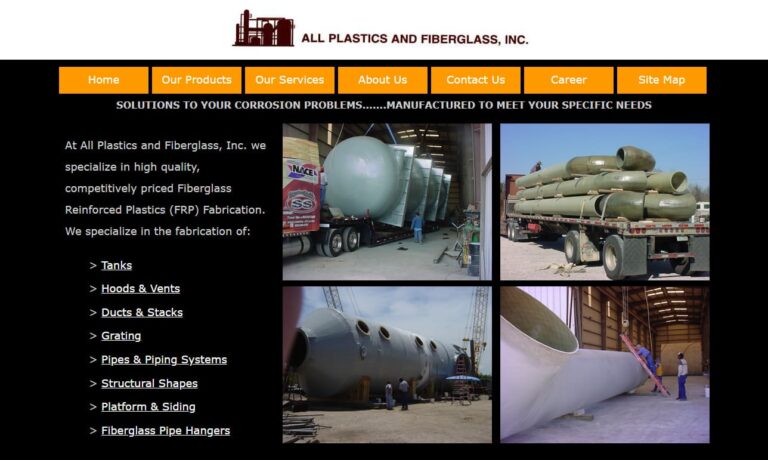

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Fabrication Companies

How Fiberglass Fabrication Is Performed

Fiberglass fabrication encompasses a series of steps that include material selection, molding, and finishing. We begin by carefully selecting high-quality raw materials, such as glass fibers and resin, known for their strength and compatibility. The process then advances with various fabrication techniques, including hand lay-up, spray-up, and filament winding.

Hand Lay-Up Fiberglass Fabrication

The hand lay-up process remains one of the most traditional and widely utilized techniques in fiberglass fabrication. We start by manually layering fiberglass sheets or mats onto a mold, saturating each layer with resin. Initially, a gel coat is applied to the mold’s surface, ensuring a smooth and glossy finish on the final product. Following this, we place the fiberglass material onto the mold and apply resin using brushes or rollers for proper impregnation and adhesion. Layer by layer, we build up the composite until the desired thickness is achieved. Finally, the composite undergoes curing, where the resin hardens, bonding the fiberglass layers together to create a strong and durable product.

Hand lay-up offers numerous strengths, making it a versatile and popular choice across various industries. One of its primary advantages is the flexibility it provides in crafting complex shapes and sizes. This manual process allows us to have precise control over the placement and orientation of the fiberglass material, making it ideal for custom or low-volume production where unique designs are necessary. Furthermore, hand lay-up requires relatively simple equipment, making it accessible to smaller manufacturers or those with limited resources. This method also enables easier integration of additional components, such as reinforcements or inserts, during the lay-up process.

Despite its versatility, hand lay-up has certain limitations we must consider. The process can be labor-intensive and time-consuming, making it less efficient for large-scale production or projects with tight deadlines. Moreover, achieving uniformity in layer thickness and resin distribution is more challenging compared to automated methods, potentially leading to variations in the final product’s mechanical properties. The manual nature of the process can also introduce a higher risk of air voids or trapped air bubbles in the composite, which may weaken the material or affect the surface finish. Additionally, hand lay-up may not be as well-suited for applications requiring extremely precise fiber orientation, which techniques like filament winding can better achieve.

Despite its limitations, hand lay-up remains a valuable fiberglass fabrication method for various industries, including marine, construction, and automotive. Companies can leverage the strengths of hand lay-up to produce custom, one-of-a-kind components with excellent strength and durability. By carefully considering project requirements and design complexity, they can determine whether hand lay-up is the ideal process to achieve the desired results.

Spray-Up Fiberglass Fabrication

The spray-up fiberglass fabrication process, also known as spray lay-up or chop spray, involves creating fiberglass composites by spraying chopped fiberglass strands and resin onto a mold or surface. In this method, we chop fiberglass rovings or continuous strands into smaller pieces and mix them with a liquid resin in a spray gun or chopper system. The mixture is then projected onto the mold, where it adheres and forms a composite layer. They repeat the process layer by layer until achieving the desired thickness.

One of the main strengths of spray-up fiberglass fabrication lies in its efficiency and speed. With the continuous application of the fiberglass and resin mixture, we can produce larger parts or surfaces relatively quickly compared to other hand lay-up methods. This makes spray-up perfect for projects that require high production rates or have time constraints. Additionally, this method ensures a more uniform and homogeneous composite structure, leading to consistent mechanical properties throughout the product. The blend of efficiency and uniformity makes spray-up ideal for applications that prioritize cost-effectiveness and structural integrity.

While spray-up offers numerous advantages, it also has certain weaknesses that need to be considered. One limitation is the lack of control over fiber orientation during the application process. Since chopped fiberglass strands are randomly projected onto the mold, achieving specific fiber orientations can be challenging compared to techniques like filament winding. This may result in reduced mechanical properties in certain directions, limiting its use in highly specialized engineering applications. Additionally, using chopped fibers can lead to higher resin content in the composite, slightly reducing its overall strength-to-weight ratio compared to other fabrication methods like hand lay-up or filament winding. Lastly, the equipment required for spray-up can be more complex and may necessitate a skilled operator, which could increase production costs for some manufacturers.

Despite these weaknesses, spray-up fiberglass fabrication remains a valuable technique for many applications, especially those requiring the rapid production of larger parts with consistent structural integrity. We can choose from various fiberglass fabrication methods based on our specific project requirements, balancing the benefits and limitations of each technique to achieve the desired results.

Filament Winding Fiberglass Fabrication

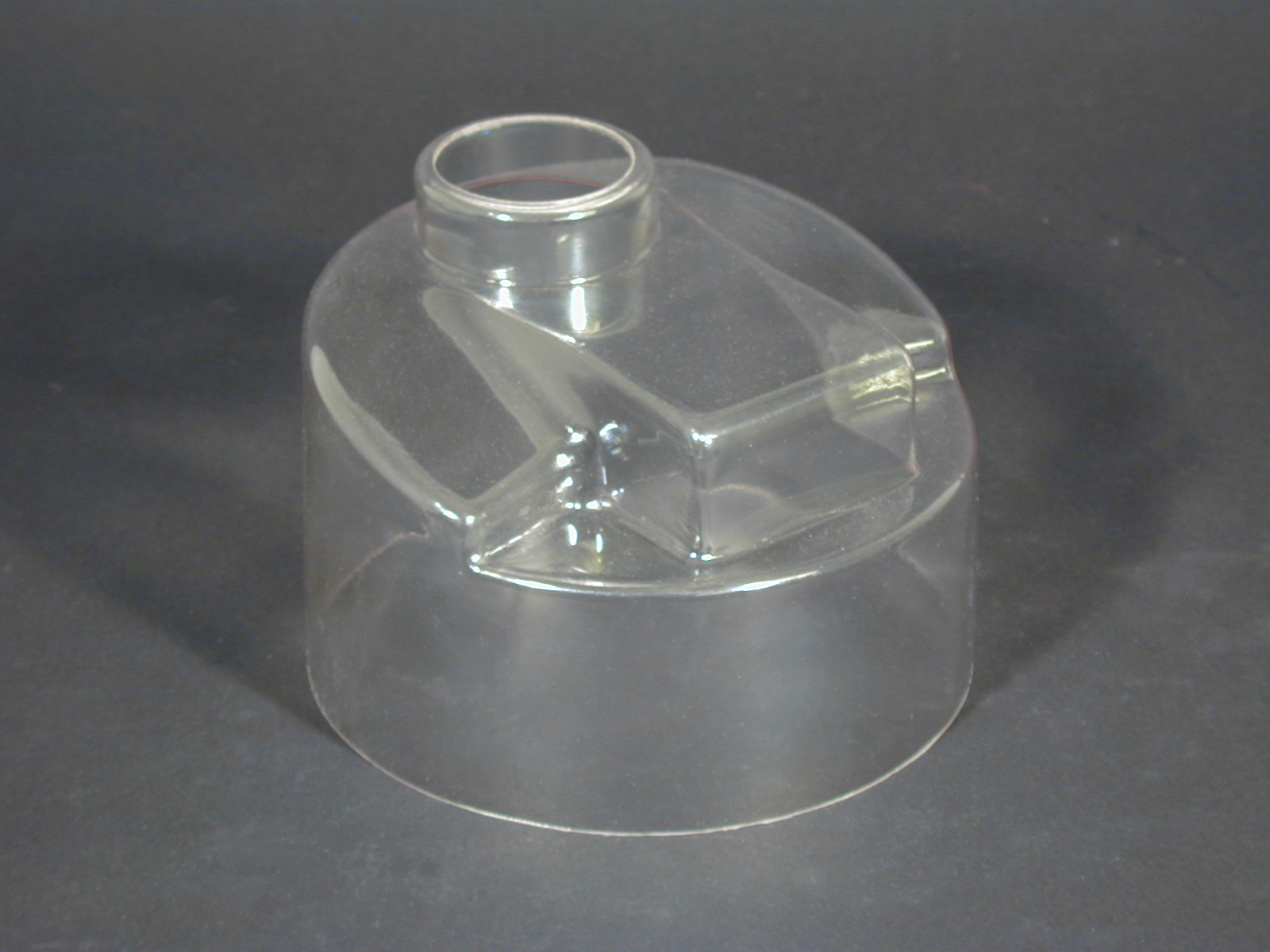

The filament winding process is a specialized technique we use in fiberglass fabrication to create cylindrical or tubular structures with exceptional strength and mechanical properties. In this method, we impregnate continuous fiberglass filaments with resin and precisely wind them onto a rotating mandrel or mold in a predetermined pattern. As the mandrel rotates, the filament is wound under tension, ensuring optimal fiber alignment along the length of the structure. Once the winding is complete, we cure the composite and remove the mandrel, leaving behind a robust and high-strength cylindrical component.

Filament winding offers numerous advantages, making it a preferred method for specific applications. One of its key benefits is the precise fiber orientation it allows, leading to exceptional mechanical properties with high tensile and flexural strength. The continuous and controlled winding process ensures that the fibers align with the load-bearing directions, boosting the component’s overall strength and performance. Furthermore, filament winding provides excellent material efficiency, using only the necessary amount of resin-impregnated fiber. This results in lightweight components, ideal for aerospace and other weight-sensitive applications. Additionally, the process enables the creation of seamless structures, reducing the risk of delamination or weak points typically found in jointed constructions.

Though filament winding is a powerful technique, it comes with certain limitations. The equipment required can be complex and costly, which may deter small-scale production or low-budget projects. This process is particularly suited for creating cylindrical or tubular structures and may not offer the same versatility as other fabrication methods like hand lay-up or spray-up for complex shapes. Additionally, the necessity of a rotating mandrel restricts the size of components that can be fabricated, as larger structures might need specialized equipment or segmented mandrels, adding to the process complexity. Lastly, the winding process itself can be time-consuming, especially for large structures, potentially impacting production timelines for time-sensitive projects.

Despite these limitations, filament winding continues to be an essential technique for producing high-strength and lightweight cylindrical components. This method is particularly useful for creating pressure vessels, pipes, rocket casings, and aerospace parts. By utilizing filament winding, manufacturers and engineers can develop robust and reliable structures that meet the strict performance standards required in industries where strength, weight, and precision are vital.

Choosing the Appropriate Technique

Choosing the most appropriate fiberglass fabrication method for a specific application involves a careful evaluation of several key factors. First, you need to understand the project requirements. Considerations such as the desired shape, size, and complexity of the component will play a significant role in determining which fabrication technique is best suited. For instance, if the application involves creating cylindrical or tubular structures with precise fiber orientation, filament winding may be the optimal choice. On the other hand, for applications requiring custom shapes or smaller production volumes, hand lay-up could provide the necessary flexibility.

Next, you need to consider the performance requirements of the final product. Evaluating factors such as mechanical strength, weight, and environmental resistance will guide us in choosing the best fabrication method to meet these criteria. For applications demanding high strength-to-weight ratios, filament winding or spray-up might be preferred due to their ability to produce lightweight yet robust components. On the other hand, if cost-effectiveness is a priority and the application requires larger quantities of simpler parts, spray-up could prove more efficient.

Another crucial aspect is production volume and timeline. For high-volume production, automated techniques like spray-up or filament winding provide greater speed and consistency. On the other hand, hand lay-up is better suited for smaller quantities or prototypes where manual craftsmanship is essential.

Moreover, you should consider the availability of resources, equipment, and skilled labor. Certain fabrication methods might need specialized machinery or expertise, which can affect the feasibility of our chosen approach. By evaluating the costs and resources needed for each technique, we can ensure that the selected method aligns with our project’s budget and capabilities.

Finally, you should not overlook environmental and safety considerations. Some fabrication methods, like spray-up, involve volatile chemicals, requiring proper safety measures and ventilation. It’s crucial to understand the environmental impact of each method and adhere to safety regulations for responsible manufacturing practices.

In conclusion, choosing the best fiberglass fabrication method demands a thorough analysis of our project’s unique needs, performance requirements, production volume, available resources, and safety considerations. By meticulously evaluating these factors and weighing the strengths and limitations of each technique, you can make informed decisions. This approach ensures the successful production of high-quality fiberglass components tailored to your specific applications.

Performers of Fiberglass Fabrication

Fiberglass fabrication can be managed either internally or through external services. Handling it in-house allows us to maintain direct control over the manufacturing process, ensuring our quality standards are met. Conversely, outsourcing this task lets us tap into specialized expertise and equipment, which is especially beneficial for complex projects or when cost-effectiveness is key. Deciding between in-house and outsourced fabrication depends on factors like production scale, available resources, and project needs.

Regulations and Requirements for Fiberglass Fabrication

When we engage in fiberglass fabrication in the United States, we must consider specific training requirements and regulatory guidelines to ensure compliance and safety. Proper training is essential, and everyone involved in fiberglass fabrication should receive thorough instruction on handling hazardous materials, such as resins and chemicals. Understanding the use of personal protective equipment (PPE) and safe work practices is vital to minimize potential health and safety risks linked to fiberglass materials. Various organizations and industry associations provide training programs and certifications focused on fiberglass fabrication, helping to enhance our skills and ensure we follow best practices.

When it comes to regulatory requirements, fiberglass fabrication is governed by occupational health and safety regulations set by the Occupational Safety and Health Administration (OSHA). Companies involved in this industry must adhere to OSHA’s standards to ensure worker protection from various workplace hazards. OSHA’s Hazard Communication Standard (HCS) requires proper labeling, handling, and storage of chemicals used in fiberglass fabrication. Additionally, manufacturers must keep Material Safety Data Sheets (MSDS) for all hazardous substances involved in the process and provide thorough training to employees on chemical hazards and safety procedures.

Moreover, we should take environmental regulations into account. Fiberglass fabrication often releases airborne particles and volatile organic compounds (VOCs), potentially affecting air quality and the environment. Adhering to the regulations set by the Environmental Protection Agency (EPA) is crucial for managing and controlling emissions from fiberglass fabrication processes and ensuring proper waste disposal.

In certain situations, fiberglass fabrication for specific applications, like in the aerospace or automotive industries, necessitates compliance with industry-specific standards and certifications. These standards typically include rigorous quality control measures and testing procedures to ensure that the fabricated fiberglass products meet industry requirements and safety standards.

Moreover, we need to consider zoning and building codes when establishing fiberglass fabrication facilities. Local authorities might have regulations concerning the location, construction, and safety aspects of manufacturing facilities to ensure the protection of nearby communities and the environment.

In summary, fiberglass fabrication in the United States requires essential training, adherence to regulatory considerations, and compliance with industry-specific standards. These measures ensure the safety of workers, compliance with environmental regulations, and the production of high-quality fiberglass products. To achieve successful and responsible fiberglass fabrication, it is crucial to stay informed about relevant regulations, pursue proper training, and implement best practices.

Overcoming Considerations Regarding Fiberglass Fabrication

Fiberglass fabrication is a versatile and widely used manufacturing process, but it does have some negative considerations and limitations. One significant issue is the potential exposure to hazardous substances during fabrication. Working with fiberglass materials can release fine glass fibers and volatile organic compounds (VOCs) from resins and chemicals, posing health risks to workers if proper safety measures are not in place. Additionally, the generation of airborne particles can affect indoor air quality, impacting the well-being of employees and surrounding environments.

To address these negative considerations, we have made significant efforts to enhance workplace safety and minimize exposure risks. Our companies have implemented stringent safety protocols, including the use of personal protective equipment (PPE) such as respirators, gloves, and protective clothing. We have also installed adequate ventilation systems and air filtration technologies to control and reduce airborne emissions, ensuring a safer working environment. Additionally, we conduct training programs focusing on safety practices and the proper handling of hazardous materials to educate our workers about potential risks and preventive measures.

Another limitation is the challenge of creating complex shapes and intricate designs using certain fabrication techniques, especially hand lay-up, which depends on manually layering materials. This can limit our ability to produce highly specialized components with detailed geometries. However, advancements in computer-aided design (CAD) software and automated manufacturing technologies have significantly improved control and precision. Techniques such as filament winding and computer numerical control (CNC) machining have made it possible to produce intricate fiberglass components with high accuracy, overcoming the constraints of traditional hand lay-up methods.

Additionally, environmental concerns surrounding the disposal and recycling of fiberglass waste have posed a significant challenge. When not properly managed, fiberglass waste contributes to landfill accumulation and environmental pollution. To tackle this issue, researchers and industry stakeholders are exploring eco-friendly alternatives and innovative recycling methods. Efforts are underway to develop composite recycling technologies that can recover and reuse fiberglass materials, thereby reducing the environmental impact and promoting sustainable manufacturing practices.

In conclusion, fiberglass fabrication presents challenges such as potential health risks, difficulties in complex shaping, and environmental concerns related to waste management. However, by prioritizing workplace safety, embracing advanced manufacturing technologies, and investing in sustainable recycling methods, we can overcome these obstacles. Through ongoing improvements and adherence to best practices, we can ensure that fiberglass fabrication becomes safer, more efficient, and environmentally responsible. This way, the fiberglass industry can sustainably meet the manufacturing needs of various sectors.

Benefits of Fiberglass Fabrication

Fiberglass fabrication provides numerous advantages, making it a popular manufacturing process across many industries. One of its primary benefits is the outstanding strength-to-weight ratio. Fiberglass composites boast remarkable mechanical properties while being much lighter than traditional materials such as steel or aluminum. This lightweight characteristic leads to lower transportation costs, enhanced fuel efficiency in vehicles, and overall improved performance in applications where weight is crucial.

Another significant benefit of fiberglass fabrication is its durability. Fiberglass composites are highly resistant to corrosion, chemicals, and weather elements. This inherent resistance ensures longevity and minimal maintenance requirements, making fiberglass products ideal for outdoor applications and harsh environments. The durability and long lifespan of fiberglass components contribute to cost-effectiveness and reduced lifecycle expenses.

The versatility of fiberglass fabrication offers us a compelling advantage. This process enables the creation of complex shapes and designs, granting engineers and designers the freedom to achieve innovative solutions for various applications. Whether we’re producing curved architectural panels, streamlined aerospace components, or custom-shaped boat hulls, fiberglass fabrication allows us to bring diverse and intricate designs to life.

Fiberglass fabrication also offers outstanding electrical and thermal insulation properties. These qualities make fiberglass components ideal for use in electrical enclosures, insulators, and thermal barriers, enhancing safety and efficiency in both electrical and industrial environments.

Furthermore, the fabrication of fiberglass provides exceptional design flexibility and customization possibilities. By adjusting the fiber orientation, resin type, and reinforcement materials, we can tailor the mechanical properties of fiberglass composites. This ability enables us to optimize characteristics such as stiffness, strength, and impact resistance, ensuring they meet the specific needs of various applications.

Lastly, fiberglass fabrication aligns seamlessly with our sustainability goals. The recyclability and eco-friendly potential of fiberglass materials have captured our attention in the quest to reduce environmental impact. Both researchers and manufacturers are actively exploring efficient methods to recycle fiberglass waste and develop eco-friendly alternatives for resins and reinforcement materials.

In conclusion, the many advantages of fiberglass fabrication—such as its excellent strength-to-weight ratio, durability, versatility, electrical and thermal insulation properties, design flexibility, and sustainability potential—have made it a top choice in industries like aerospace, automotive, construction, and marine. With ongoing advancements in material science and manufacturing processes, fiberglass fabrication is set to play an even more critical role in meeting the changing demands of various industries, contributing to a more sustainable and efficient future.

Applications of Fiberglass Fabrication

Fiberglass fabrication is extensively applied across numerous industries due to its exceptional properties and versatility. In construction and architecture, we frequently see fiberglass used for roofing, cladding, and decorative elements. Its lightweight nature and moldability into intricate shapes make fiberglass perfect for crafting aesthetically appealing structures and façades.

The transportation industry reaps substantial benefits from fiberglass fabrication. In automobiles, buses, and trains, fiberglass components are widely used to reduce weight, boost fuel efficiency, and enhance overall performance. Additionally, the aerospace and aviation sectors employ fiberglass composites for aircraft interiors, radomes, and various structural components, thanks to their impressive strength-to-weight ratio and resistance to environmental conditions.

In the marine and boating industry, we extensively utilize fiberglass fabrication for boat hulls, decks, and various marine equipment. Fiberglass’s corrosion-resistant properties and ability to withstand harsh marine environments make it our preferred material for marine applications.

In the sports and recreational equipment sector, fiberglass plays a crucial role in crafting items like kayaks, surfboards, golf clubs, and fishing rods. Its strength, durability, and flexibility enhance the performance and overall experience for users of these products.

Furthermore, fiberglass fabrication plays a vital role in industrial and manufacturing sectors. We utilize it to produce storage tanks, ductwork, and custom fabrications. Its resistance to chemicals and corrosion makes fiberglass a dependable option for storing and transporting various substances.

The renewable energy sector has embraced fiberglass fabrication for manufacturing wind turbine blades. The lightweight and durable properties of fiberglass composites make them ideal for efficiently capturing wind energy.

Additionally, fiberglass fabrication has been embraced by the electrical and electronics industry. We find fiberglass components in electrical enclosures, circuit boards, and insulating materials because of their superior electrical and thermal insulation properties.

Overall, the diverse applications of fiberglass fabrication across industries showcase its importance as a versatile and valuable manufacturing process. As technology and materials advance, fiberglass fabrication is likely to play an even greater role in various sectors, offering innovative solutions and driving progress in multiple industries.

Choosing the Right Fiberglass Fabrication Business

To achieve the best results when selecting a fiberglass fabrication business, it’s essential to compare several companies using our directory. Each company profile showcases their expertise and capabilities, along with a contact form for direct communication or quote requests. Utilize our website previewer to swiftly understand each company’s specialties. Finally, use our straightforward RFQ form to contact multiple businesses with the same request.

Fiberglass Fabricators

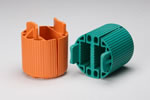

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services