Fiberglass rods are an important material used in a variety of industries. They are made of glass fibers that have been woven into a fabric and then impregnated with a resin, creating a strong and durable material. In this article, we will discuss the variations of fiberglass rods, their limitations, benefits, and applications. Read More…

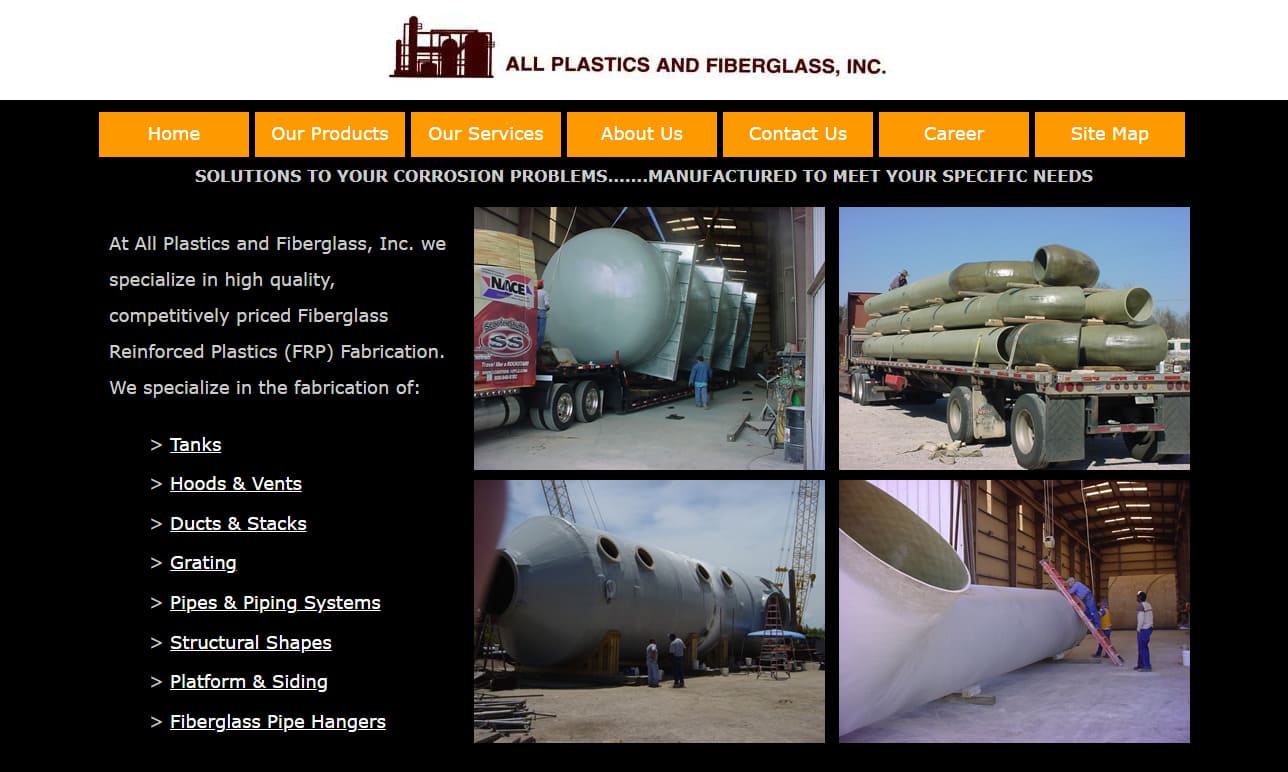

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Rod Companies

Creating Fiberglass Rods with Pultrusion

Fiberglass rods are created using a process called pultrusion. The process begins with glass fibers, which are typically made from silica or other minerals, being coated with a resin such as epoxy or polyester. The resin-coated fibers are then fed through a machine that pulls them through a series of dies that shape and cure the material into a rod shape.

The pultrusion process involves several stages, including:

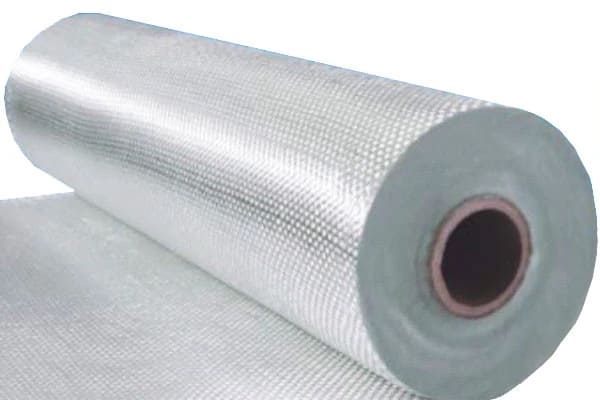

- Fiberglass Reinforcement: Fiberglass reinforcement is typically in the form of continuous strands or rovings.

- Resin Impregnation: The reinforcement is coated with a liquid resin, which is typically a thermosetting resin.

- Pre-Forming: The impregnated reinforcement is shaped into the desired profile or cross-section using a pre-forming die.

- Pultrusion: The pre-formed reinforcement is pulled through a heated die, which cures the resin and produces a solid, continuous rod.

After the pultrusion process, the fiberglass rod may undergo additional finishing steps, such as cutting to length, sanding, and coating with a protective layer. The finished fiberglass rod has the strength, durability, and resistance for many applications.

Variations of Fiberglass Rods

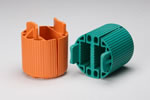

Different fiberglass rods are available, including solid fiberglass rods, hollow fiberglass rods, and pultruded rods. Solid fiberglass rods are made of a single fiberglass layer and are commonly used in electrical and marine applications. Hollow fiberglass rods are used in the construction and aerospace industries. Pultruded fiberglass rods are a specialized type of fiberglass rod made by pulling fibers through a resin bath and then through a heated die to shape the rod. This type of fiberglass rod is used in high-performance applications.

Benefits & Disadvantages of Fiberglass Rods

Fiberglass rods have many advantages. They are lightweight, strong, and resistant to corrosion. Fiberglass rods also have excellent electrical insulation properties, making them ideal for electrical applications. Additionally, they are easy to mold and shape, allowing for customized designs and manufacturing.

While fiberglass rods have many advantages, they also have some limitations. For example, fiberglass rods can be brittle and may not be able to withstand high-impact stresses. Fiberglass rods may gradually degrade when exposed to UV radiation, heat, and moisture.

Applications of Fiberglass Rods

As previously mentioned, fiberglass rods have a wide range of applications due to their combination of high strength, low weight, and excellent corrosion resistance. Here are some specific applications for fiberglass rods:

Electrical Insulators

Fiberglass rods are used as electrical insulators in power transmission and distribution systems. They offer good electrical insulation and can withstand high voltage without conducting electricity.

Aerospace

Fiberglass rods are used in the aerospace industry to make parts such as antennas, control surfaces, and wing supports. They are lightweight and offer excellent strength, making them ideal for aerospace applications.

Marine

Fiberglass rods are used extensively in the marine industry for applications such as boat hulls, masts, and supports. They are resistant to saltwater and other corrosive elements, making them an ideal material for marine applications.

Automotive

Fiberglass rods are used in the automotive industry to construct body panels, spoilers, and aerodynamic components. They are lightweight, strong, and have good impact resistance, making them an ideal material for high-performance automotive applications.

Sports Equipment

Fiberglass rods are used in sports equipment, such as fishing rods, hockey sticks, and bows. They offer excellent flexibility and strength, making them ideal for these applications.

Construction

Fiberglass rods are used in construction to reinforce concrete and other building materials. They are lightweight and easy to work with, and they offer excellent strength and corrosion resistance.

Wind Energy

Fiberglass rods are used in the manufacture of wind turbine blades. They offer high strength and stiffness, making them an ideal material for large wind turbine blades.

Medical Devices

Fiberglass rods are used to manufacture various medical devices, such as surgical instruments and braces. They offer good strength and flexibility, making them an ideal material for these applications.

Choosing the Correct Fiberglass Rod Supplier

To ensure you have the most productive outcome when purchasing fiberglass rods from a fiberglass rod supplier, it is important to compare several fiberglass rod suppliers using our directory of fiberglass rod suppliers. Each fiberglass rod supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier or request a quote. Review each fiberglass rod business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to compare several fiberglass rod companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services