Fiberglass pipes have emerged as a reliable and versatile solution for various industries. Composed of reinforced plastic material, these pipes offer exceptional performance and durability in a wide range of applications. Whether it’s transporting corrosive chemicals, managing wastewater, or facilitating the flow of oil and gas, fiberglass pipes have proven their worth. Read More…

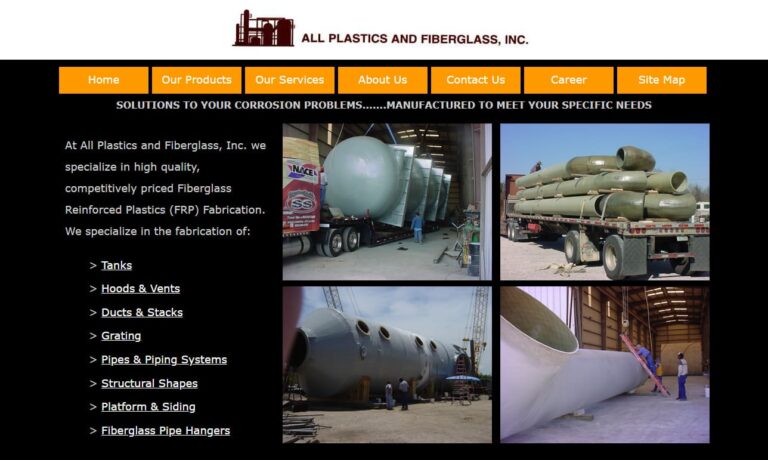

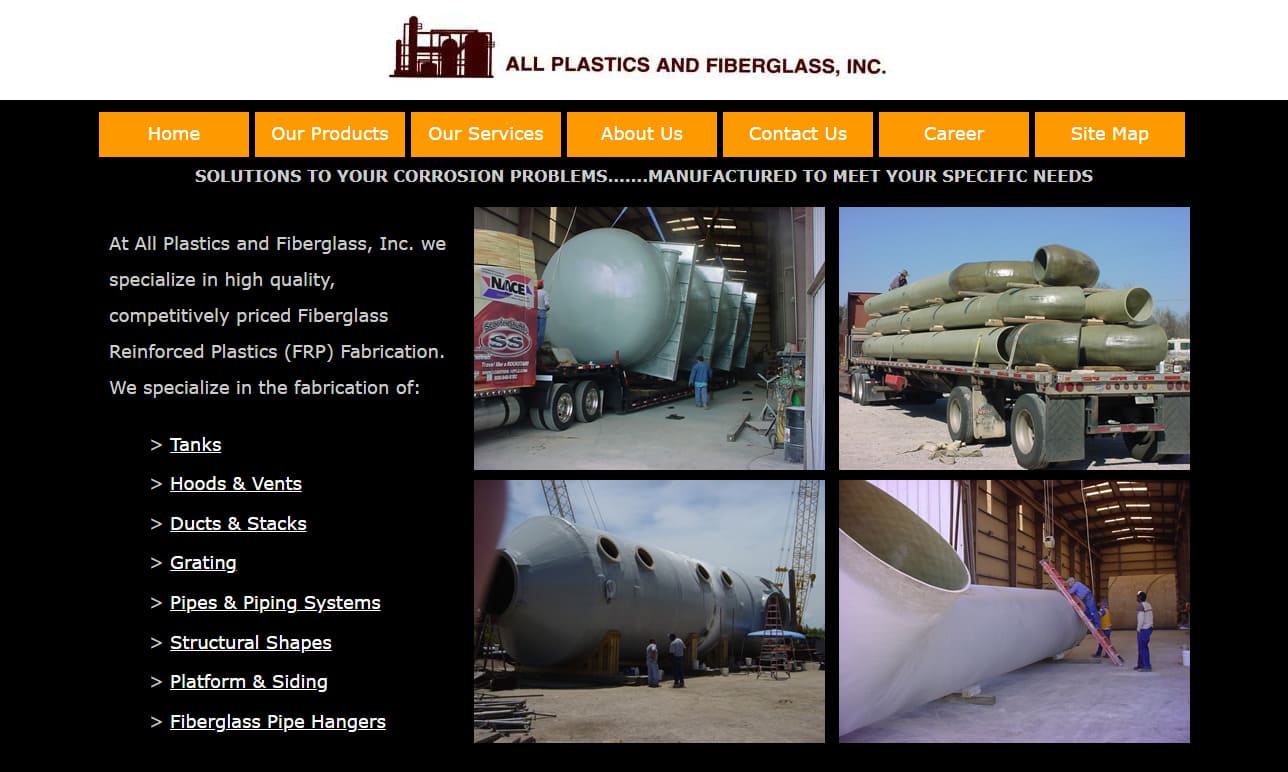

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

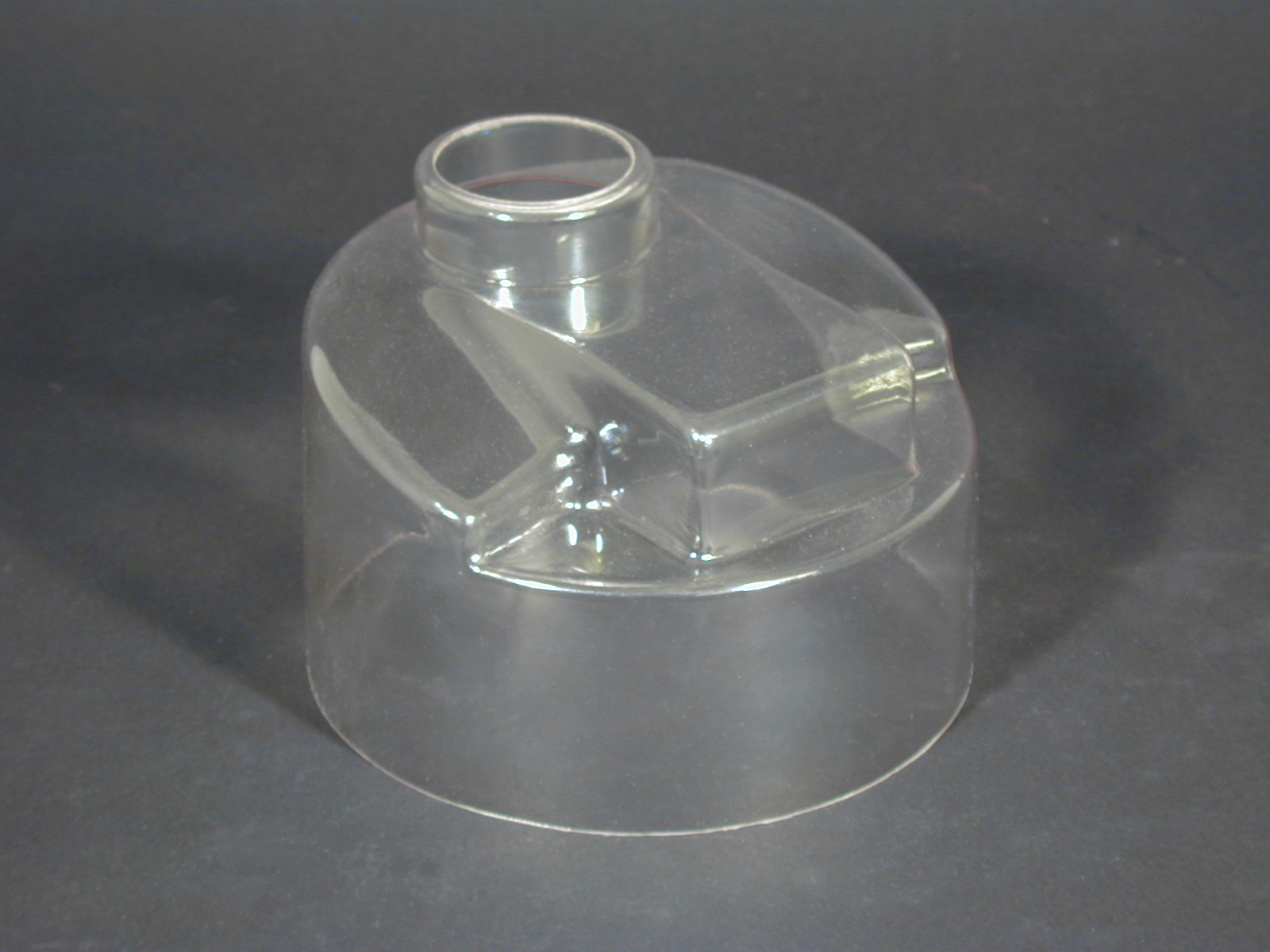

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Pipe Companies

Creation of Fiberglass Pipes

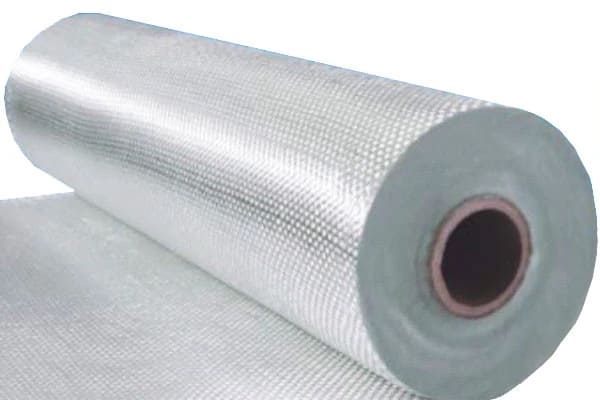

Fiberglass pipes are manufactured using different processes, each catering to specific requirements. The filament winding process involves winding continuous strands of fiberglass around a rotating mandrel, resulting in high-strength pipes. This process finds its application in the demanding oil and gas industry, where resistance to corrosive substances and high-pressure environments is crucial. Alternatively, the centrifugal casting process creates pipes by spinning a mold filled with fiberglass material, enabling the production of large-diameter pipes suitable for municipal water and wastewater systems. Moreover, the hand lay-up process involves manually layering fiberglass sheets and resin, making it suitable for applications in chemical processing plants.

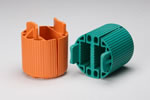

Variations of Fiberglass Pipes

Fiberglass pipes are available in various types, depending on the composition of fiberglass materials. E-glass, S-glass, and C-glass are common types of glass compositions used in fiberglass manufacturing. E-glass is a type of alkali-lime glass that is commonly used in fiberglass production due to its excellent mechanical strength and chemical resistance. S-glass is a high-strength glass composition that contains a higher percentage of alumina and offers superior tensile strength compared to E-glass. C-glass is yet another type of glass composition with increased resistance to chemical corrosion, making it suitable for applications where exposure to corrosive substances is a concern. As a result of their distinct properties, E-glass fiberglass pipes are ideal for industrial manufacturing processes. On the other hand, S-glass fiberglass pipes find application in demanding aerospace and defense sectors. Additionally, C-glass fiberglass pipes are commonly used in marine and offshore structures due to their ability to withstand harsh environments.

Considerations Regarding Fiberglass Pipes

While fiberglass pipes offer numerous benefits, there are some considerations to keep in mind. To begin with, the production of fiberglass has an environmental impact due to the use of resins and energy-intensive manufacturing processes. Additionally, fiberglass pipes may experience thermal expansion and contraction, requiring careful design considerations to accommodate temperature variations. Lastly, fiberglass pipes have limited flexibility and can be susceptible to cracking under excessive stress or impact, necessitating proper handling and installation.

Manufacturers' Efforts to Address These Considerations

Manufacturers of fiberglass pipes have made concerted efforts to address the considerations associated with their production and usage. To minimize the environmental impact, for example, they are adopting eco-friendly materials and employing more sustainable manufacturing techniques. By incorporating expansion joints into fiberglass pipe systems for improved thermal expansion and contraction, meanwhile, they are mitigating the risk of structural damage. Additionally, manufacturers are employing reinforcement techniques, such as adding layers of fiberglass or incorporating composite materials, to enhance the flexibility and durability of their pipes and make them more resistant to cracking.

Benefits of Fiberglass Pipes

Fiberglass pipes offer several advantages that contribute to their widespread usage across industries. Their exceptional corrosion resistance ensures long service life, reducing maintenance costs and downtime. Additionally, fiberglass pipes possess a high strength-to-weight ratio, making them lighter and easier to transport and install compared to traditional metal pipes. The smooth internal surface of fiberglass pipes also minimizes friction and scale buildup, ensuring efficient fluid flow. Furthermore, their low thermal conductivity helps maintain consistent fluid temperatures and reduces heat loss.

Applications of Fiberglass Pipes

The applications of fiberglass pipes are extensive and diverse. In the chemical and petrochemical industries, fiberglass pipes efficiently handle the transportation of corrosive chemicals, acids, and alkalis. Additionally, water and wastewater treatment plants rely on their durability and resistance to corrosion for efficient management of fluids. In the oil and gas industry, meanwhile, fiberglass pipes are used for pipelines, providing reliable and long-lasting solutions for fluid transport. Fiberglass pipes also find applications in infrastructure and construction projects, where their lightweight nature and corrosion resistance are highly valued. Moreover, they play a vital role in industrial manufacturing processes, facilitating the safe and efficient transportation of various fluids and chemicals. Furthermore, fiberglass pipes are utilized in the aerospace and defense sectors for their high tensile strength and resistance to extreme conditions, ensuring reliable performance in critical applications. Finally, fiberglass pipes find extensive application in marine and offshore structures, providing reliable and corrosion-resistant solutions for fluid transport in challenging marine environments.

Choosing the Right Fiberglass Pipe Supplier

To ensure you have the most constructive outcome when purchasing fiberglass pipes from a fiberglass pipe supplier, it is important to compare several companies using our directory of fiberglass pipe suppliers. Each fiberglass pipe supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each fiberglass pipe business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple fiberglass pipe companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services