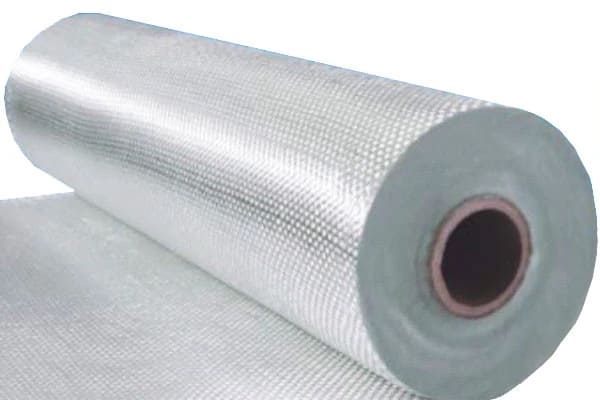

These fibers are woven together in order to create reinforcement or prevent heat from passing through. Read More…

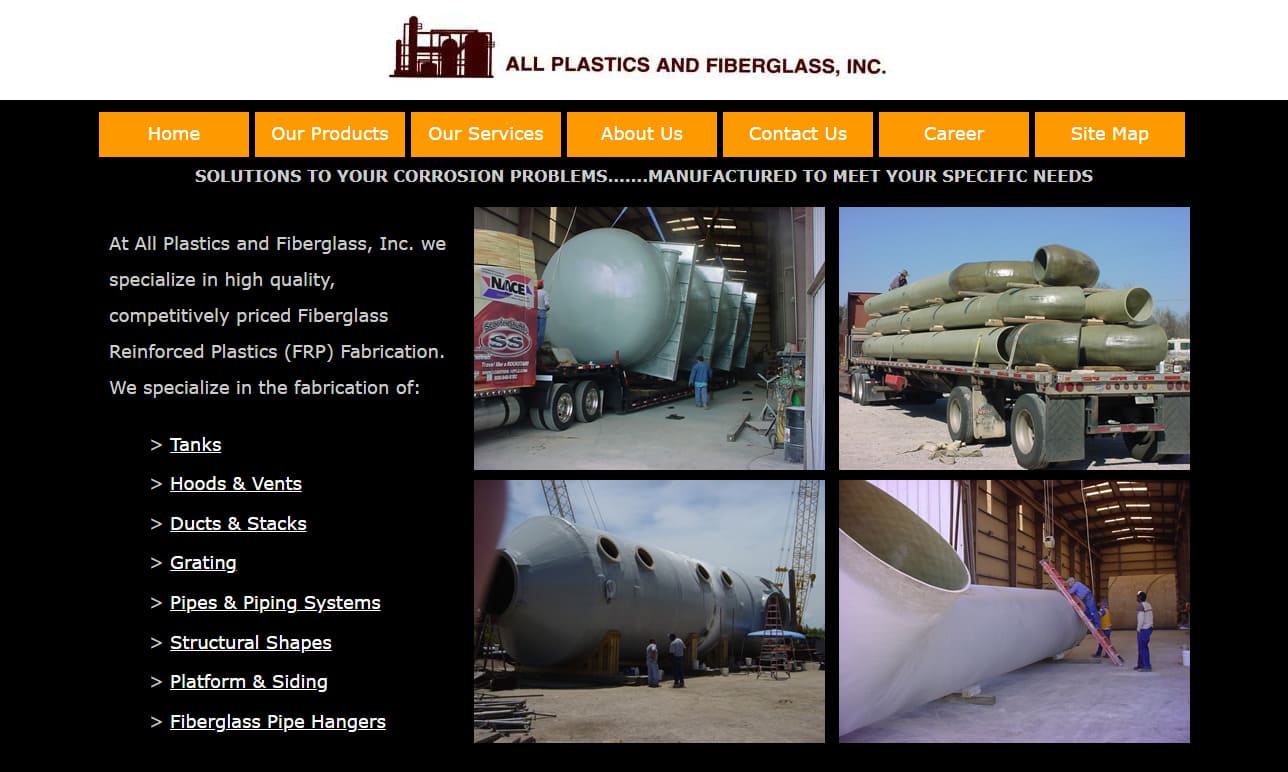

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

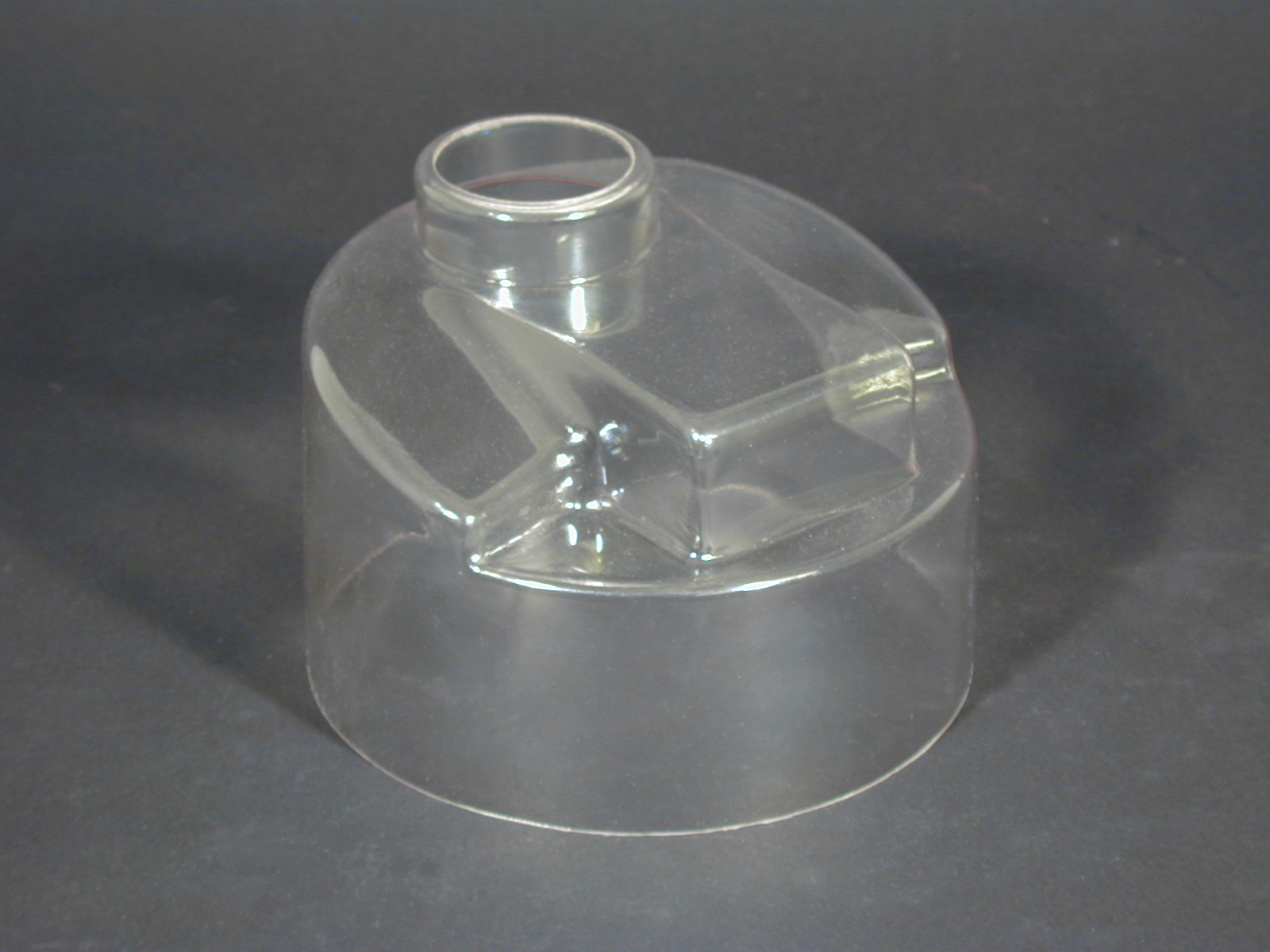

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Companies

This form of reinforcement is typically used within a plastic material and the glass fibers are arranged in a certain way depending on your application and the different requirements you may have of the fiberglass product. Fiberglass itself can be found in a vast number of industries and applications such as boats, bath tubs, automobiles, swimming pools, water tanks, roofing, pipes, casts, and many other uses.

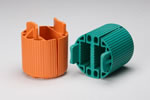

Fiberglass has a number of different properties that allow it to excel in this wide range of applications, it has rating for both compression and tension, it is weather resistant, comes with a variety of surface texture options, and is naturally resistant to a number of different corrosive elements. Fiberglass is manufactured through a process called pultrusion, which is a form of extrusion. However it differs from extrusion in that the process pulls the material as opposed to traditional extrusion methods where the material is pushed through the process.

This process pulls the different materials needed to make the fiberglass either thermoplastic or thermosetting plastic in addition to the glass fibers and takes them through a series of processes. These processes include passing through a tension roller, soaking in resin, passing through a heat source, one final pass through the pulling mechanism to completion. As stated before, fiberglass can be used in wide range of applications so the manufacturing process may differ depending on the manufacturer's preferred methods and any specific requirements you may have.

There are a number of different types of fiberglass, common types range from polyester resin which is not reinforced and has a low tensile and compression strength of 55 megapascals (MPa) and 140 MPa respectively. To S-Glass Epoxy composite which has a tensile strength of 2,358 MPa and a compression strength higher than 350 MPa. In order to determine which type of fiberglass is best for your specific application, consult with an experience fiberglass manufacturer today.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services