Fiberglass tanks have emerged as a reliable and versatile solution for various storage needs. Composed of layers of fiberglass reinforced with resin, these tanks offer exceptional durability and resistance to corrosion, making them suitable for a wide range of applications. From water storage to chemical containment, oil and gas storage to wastewater treatment, fiberglass tanks have proven their worth across industries. Read More…

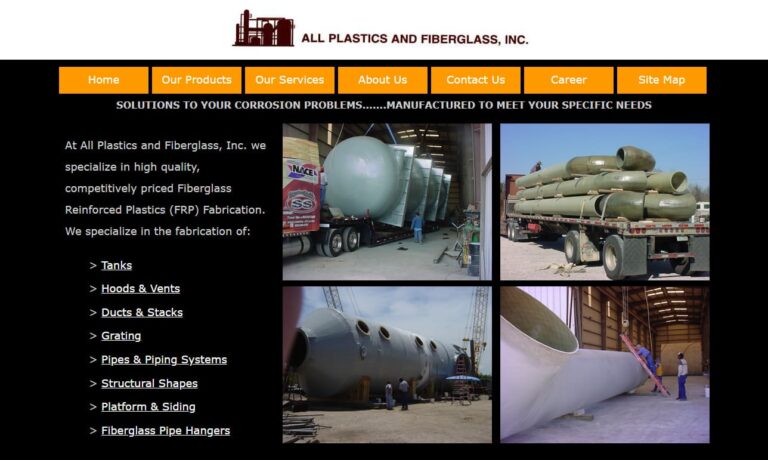

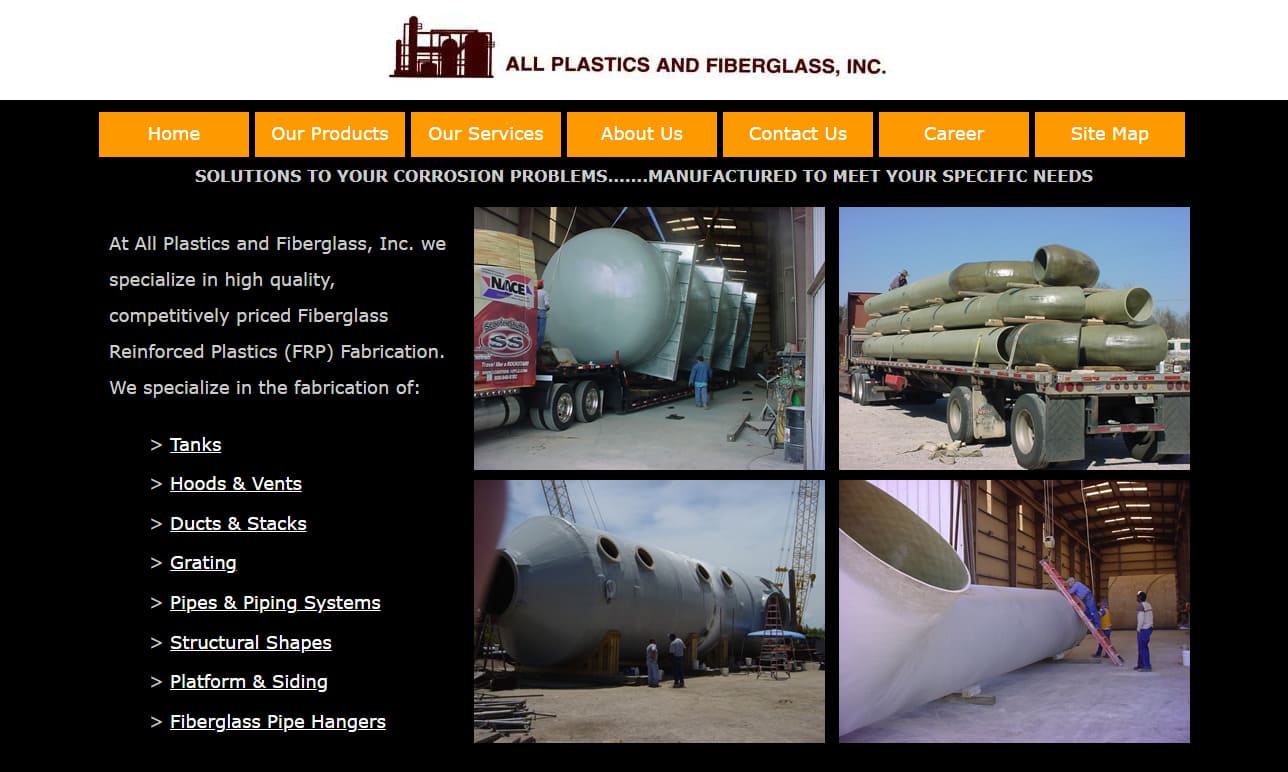

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

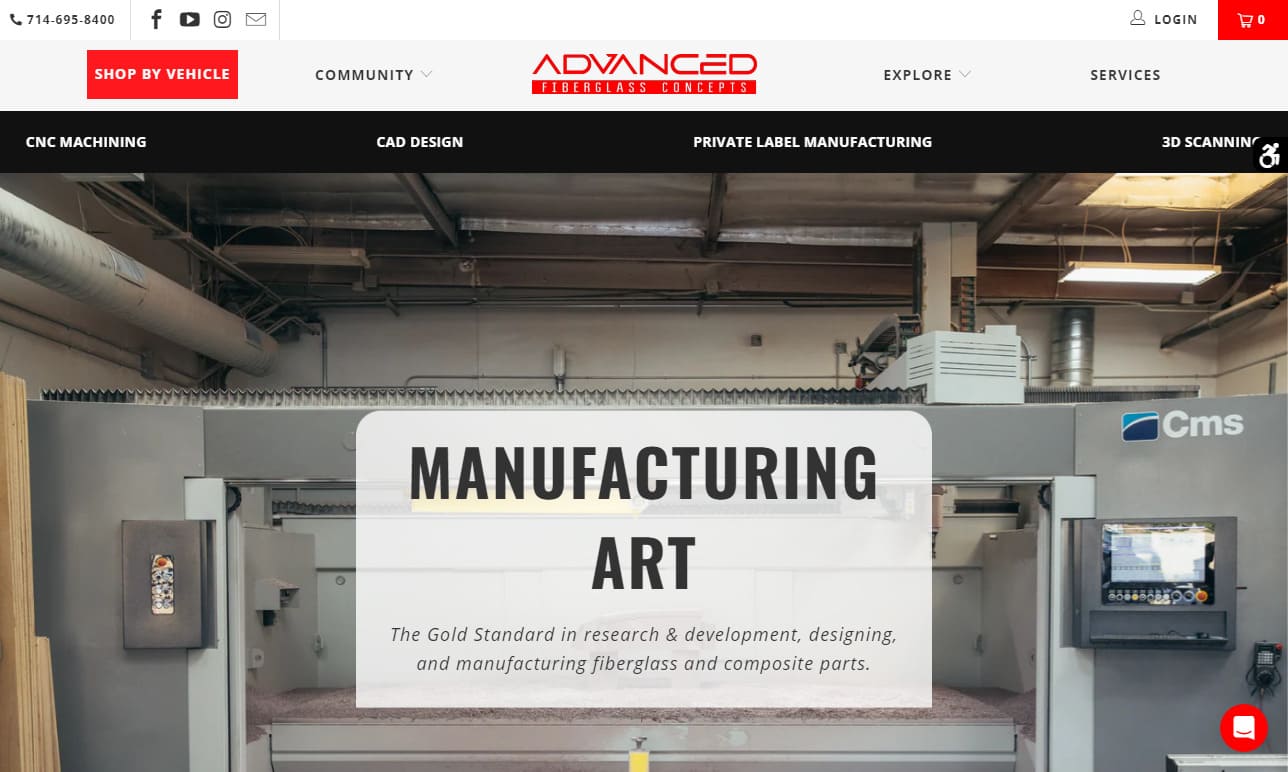

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Tank Companies

Process of Creating Fiberglass Tanks

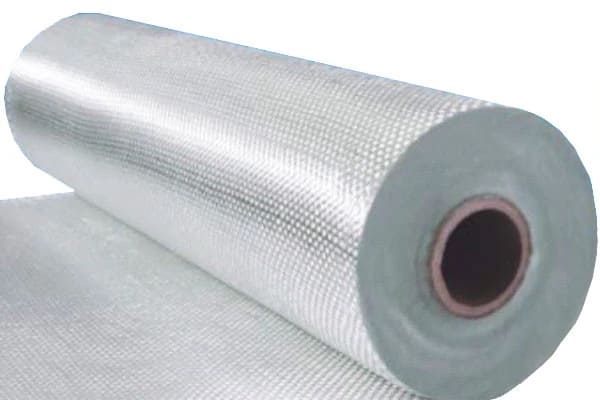

The manufacturing process of fiberglass tanks involves several variations, each tailored to specific applications. The hand lay-up method is commonly employed for water storage tanks, where layers of fiberglass and resin are manually applied to a mold. For chemical storage tanks, meanwhile, the filament winding method is preferred, as it creates a robust structure by precisely winding continuous fibers over a rotating mold. Septic tanks, on the other hand, are commonly manufactured using the spray-up method, where a spray gun is used to apply layers of resin and chopped fiberglass. Finally, oil and gas storage tanks often utilize the vacuum infusion method, which ensures optimal resin distribution throughout the structure. The vacuum infusion method for creating fiberglass tanks involves using a vacuum to evenly distribute resin throughout the fiberglass layers, resulting in a strong and high-quality composite structure.

Considerations Regarding Fiberglass Tanks

While fiberglass tanks offer numerous advantages, certain considerations should be acknowledged. During the creation and use of fiberglass tanks, factors such as proper installation, support, and regular maintenance are crucial for optimal performance. Environmental impact concerns arise from the disposal of damaged or decommissioned fiberglass tanks, necessitating proper recycling or disposal methods. Additionally, fiberglass tanks may have structural limitations in terms of size and shape, requiring careful engineering for larger or uniquely shaped tanks. Chemical compatibility limitations should also be taken into account, ensuring the suitability of fiberglass tanks for specific chemicals.

Manufacturers’ Efforts to Address These Considerations

Manufacturers of fiberglass tanks have been actively addressing these considerations through ongoing research and development. For example, advancements in material technology have led to the formulation of high-performance resins that enhance resistance to harsh chemicals, temperature fluctuations, and UV degradation. Meanwhile, reinforcement techniques, such as adding additional layers or incorporating specialized reinforcements like carbon fiber, have improved structural integrity and load-bearing capacity. Furthermore, rigorous testing and quality control procedures have been implemented to ensure compliance with industry standards, further enhancing the reliability and performance of fiberglass tanks.

Benefits of Fiberglass Tanks

Fiberglass tanks offer a multitude of benefits that make them a preferred choice for various industries and applications. One key advantage is their exceptional corrosion resistance. Unlike metal tanks that can rust or corrode over time, fiberglass tanks are impervious to corrosion, ensuring long-term durability and reducing the need for expensive maintenance or protective coatings. Additionally, fiberglass tanks are remarkably lightweight without compromising strength. This characteristic simplifies transportation, installation, and repositioning processes, saving time and resources. The high strength-to-weight ratio of fiberglass allows for efficient use of materials, resulting in cost-effective tank construction without sacrificing structural integrity.

Another significant benefit of fiberglass tanks is their longevity and durability. Fiberglass is highly resistant to extreme weather conditions, including UV radiation, thermal expansion, and contraction, as well as moisture exposure. This resilience ensures that fiberglass tanks can withstand harsh environments and maintain their integrity over an extended period. Furthermore, fiberglass tanks require minimal upkeep. The seamless design of these tanks eliminates joints and seams that can deteriorate or leak, reducing the risk of failure and associated maintenance costs. Regular inspections and simple cleaning procedures are usually sufficient to keep fiberglass tanks in optimal condition.

Easy installation and maintenance are additional advantages of fiberglass tanks. Their lightweight nature makes them easier to handle during installation or relocation, reducing labor and equipment requirements. Fiberglass tanks often come pre-fabricated or can be custom-built to fit specific site requirements, further streamlining the installation process. Additionally, fiberglass tanks are relatively low maintenance, as they do not require frequent repainting, recoating, or specialized cleaning procedures. This translates to reduced downtime and operational costs for businesses.

Furthermore, fiberglass tanks offer excellent versatility in design and customization. They can be manufactured in various shapes and sizes, allowing for efficient space utilization and accommodating specific site constraints. Fiberglass tanks can be tailored with additional features such as baffles, fittings, and accessories to meet the unique needs of different applications. This adaptability ensures that fiberglass tanks can be effectively utilized in a wide range of industries.

Applications of Fiberglass Tanks

The versatility of fiberglass tanks is evident in their wide array of applications. In water and wastewater treatment, fiberglass tanks serve as reliable storage vessels for both potable water and wastewater treatment processes, ensuring safe and clean water supplies. Additionally, chemical and industrial storage often rely on fiberglass tanks to contain corrosive substances, acids, or hazardous materials securely. The oil and gas industry also benefits from the durability and resistance of fiberglass tanks, storing fuels, oils, and other substances for exploration, production, and distribution operations. Meanwhile, fiberglass tanks find utility in agriculture and aquaculture as well, enabling efficient storage of fertilizers, pesticides, and water for irrigation systems. Likewise, fiberglass tanks play a vital role in fire suppression systems, providing reliable water storage for firefighting efforts. Finally, septic tanks made from fiberglass offer a sanitary and durable solution for the efficient disposal and treatment of domestic wastewater.

Choosing the Right Fiberglass Tank Supplier

To ensure you have the most productive outcome when purchasing a fiberglass tank from a fiberglass tank supplier, it is important to compare several companies using our directory of fiberglass tank suppliers. Each fiberglass tank supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each fiberglass tank business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple fiberglass tank suppliers with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services