Fiberglass panels have become a ubiquitous presence in various industries due to their exceptional strength, durability, and versatility. These panels consist of layers of glass fibers embedded in a matrix of resin, resulting in a lightweight yet sturdy material. Their widespread use can be attributed to their ability to meet the diverse needs of different applications, ranging from construction and automotive to aerospace and renewable energy. Read More…

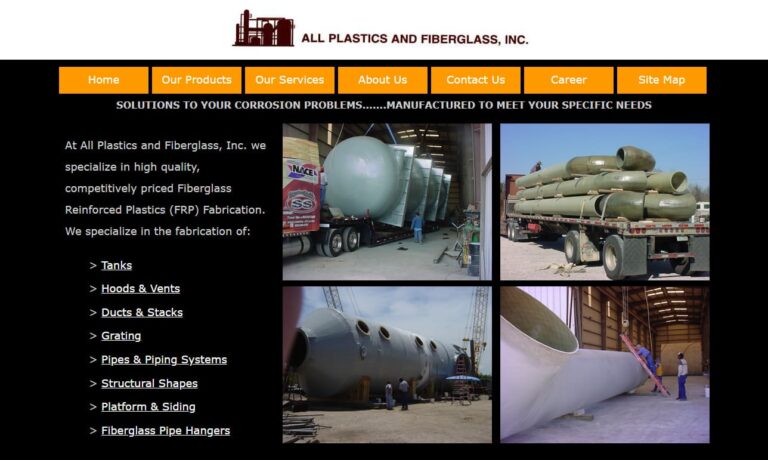

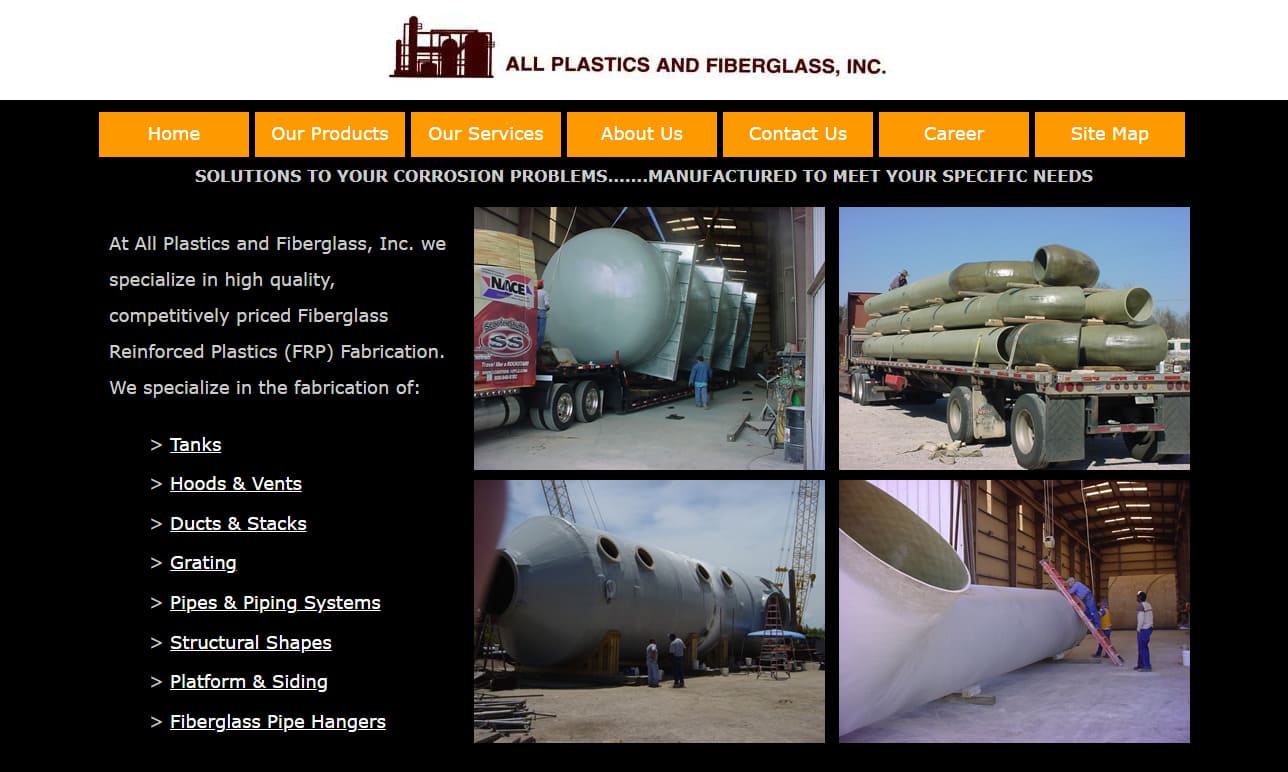

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your fiberglass needs. No matter how large or small the job is, AP & F is committed to a process that ensures the highest quality fiberglass fabrications.

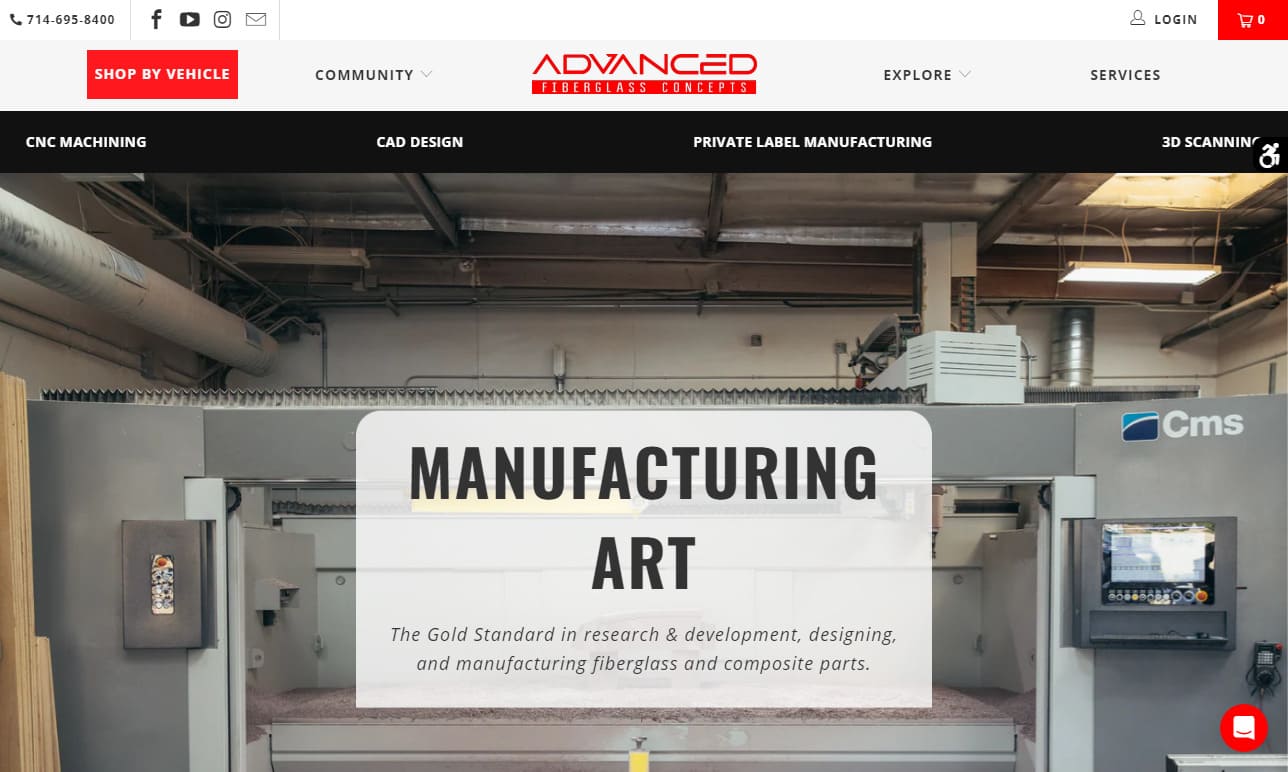

Advanced Fiberglass Concepts (ADV) is a leading provider of high-quality composite products and solutions for various industries. With a commitment to innovation, exceptional craftsmanship and customer satisfaction, ADV has established itself as a trusted name in the composite manufacturing industry. ADV has the vision and capabilities to deliver advanced composite solutions that meet the...

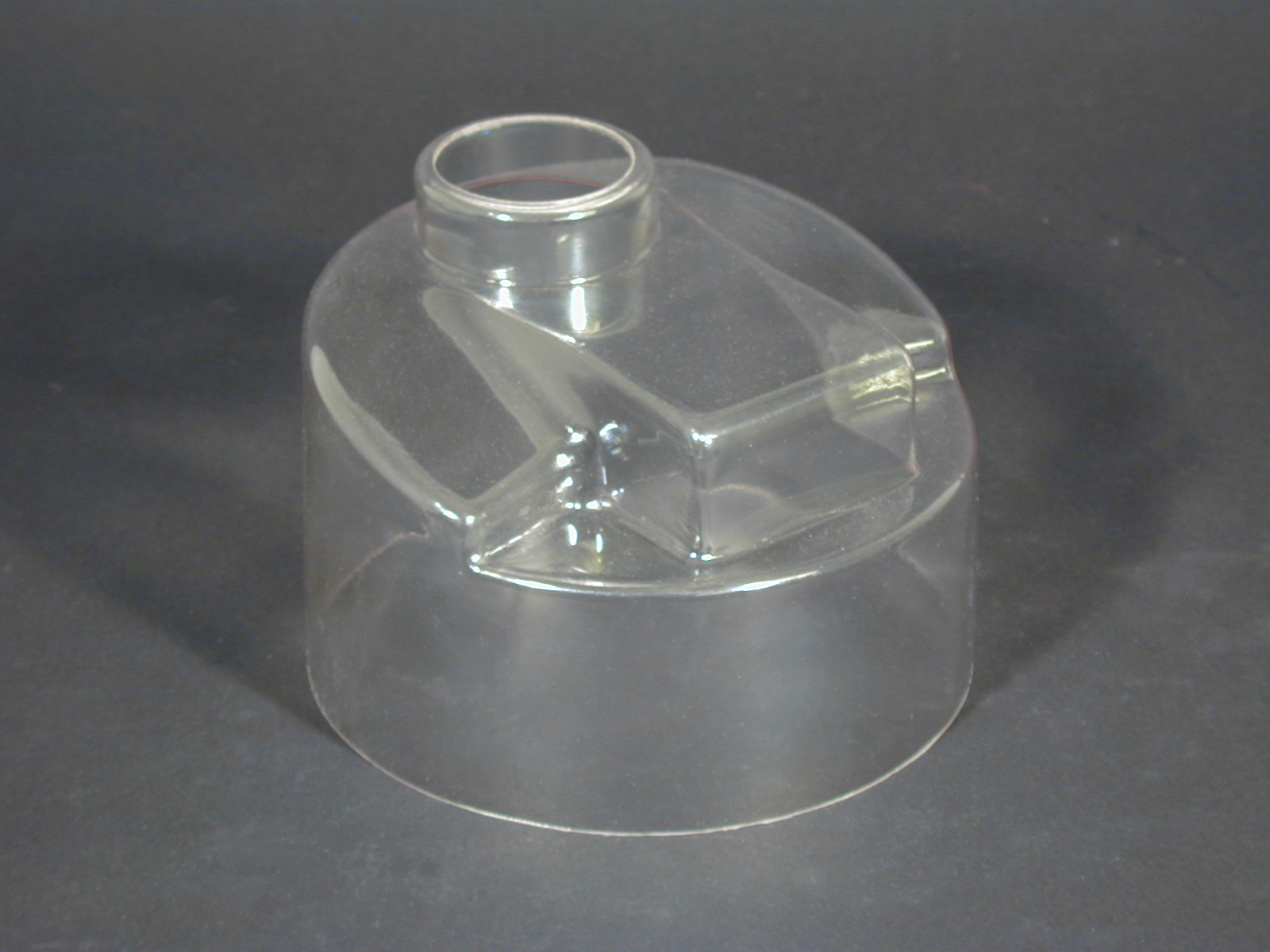

We are a professional fiberglass manufacturer that creates a wide variety of parts for companies and consumers across the country. Products including package chutes, seat pans and bottoms, battery covers, skate car and our most trusted walk in bathtubs known worldwide. Consistency of performance and quality is our first mission. Contact us today for more information.

Arrowhead has been in the composite molding business since 1972. We supply parts to many different customers in a variety of different industries. Such industries include but are not limited to: agriculture, truck and bus, marine, transportation, commercial and specialty vehicle and equipment manufacturers. We specialize in both open and closed molding and have many years of experience converting ...

Since the 1950’s, Beetle Plastics has been a designer and manufacturer of composite and fiberglass products. We specialize in cooling tower piping, and also offer fiberglass tanks, vessels, and processing equipment. We offer composite and fiberglass fabrication to meet your needs.

More Fiberglass Panel Companies

Creation of Fiberglass Panels

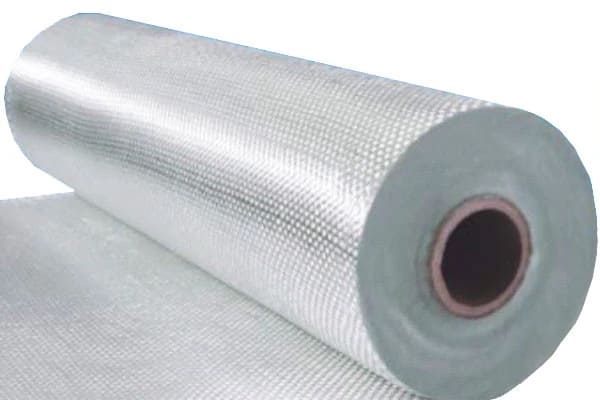

The process of creating fiberglass panels typically involves several key steps. First, glass fibers are impregnated with a resin, such as polyester or epoxy, to form a composite material. Next, the composite material is shaped into panels using different techniques, including hand-layup, spray-up, or vacuum infusion. Each method has its specific advantages in terms of cost, production speed, and surface finish.

Variations in Fiberglass Panel Creation

The hand-layup method involves manually layering the resin-impregnated fibers onto a mold, ensuring proper distribution and alignment. This technique is commonly used for small-scale production and enables intricate designs. An example application is the manufacturing of custom-made fiberglass parts for art installations. On the other hand, the spray-up method employs a spray gun to simultaneously deposit the resin and fibers onto a mold, making it suitable for larger and simpler shapes. It is widely utilized in industries such as automotive, where it facilitates the production of vehicle body panels. Additionally, the vacuum infusion method employs a vacuum to draw resin into pre-placed dry fibers, resulting in a high-strength, void-free laminate. This technique finds its application in the production of large-scale structures like wind turbine blades.

Considerations Regarding Fiberglass Panels

While fiberglass panels offer numerous advantages, there are some considerations to keep in mind. One aspect is the environmental impact associated with the production process, as it involves the use of non-renewable resources and the emission of volatile organic compounds. Another consideration is the inherent brittleness of fiberglass, which may restrict its use in certain load-bearing applications. Additionally, fiberglass panels have relatively high thermal conductivity, making them less suitable for insulating purposes.

Manufacturer Efforts to Address Considerations

Manufacturers have made significant efforts to address the environmental impact of fiberglass panels. They have developed eco-friendly resins, such as bio-based or recycled resins, which reduce reliance on fossil fuels and minimize emissions. To enhance structural performance, meanwhile, reinforcement techniques like adding additional layers, using foam cores, or incorporating carbon fibers have been employed. Furthermore, manufacturers have introduced innovative thermal insulation solutions, such as incorporating insulating foam or creating multi-layered composite structures, to mitigate the thermal conductivity limitations.

Benefits of Fiberglass Panels

Fiberglass panels provide several notable benefits that contribute to their widespread adoption across various industries.To start, their lightweight nature coupled with high strength is a key advantage. These panels offer an exceptional strength-to-weight ratio, making them an ideal choice for applications where weight reduction is crucial. This includes industries such as aerospace and automotive where the combination of strength and low weight is highly desirable. Additionally, the lightweight characteristic of fiberglass panels allows for easier handling, transportation, and installation, while still providing the necessary structural integrity for the intended applications. Whether it's reducing fuel consumption in aircraft or improving overall performance in automobiles, the lightweight nature of fiberglass panels proves advantageous in numerous scenarios.

Applications of Fiberglass Panels

The versatility of fiberglass panels is evident in their extensive range of applications. In the construction industry, they are used for cladding, roofing, and interior components, providing excellent weather resistance and aesthetic appeal. In the automotive sector, meanwhile, fiberglass panels find their place in body panels, hoods, and fenders, offering lightweight alternatives to traditional materials. The aerospace industry also utilizes fiberglass panels in aircraft interiors, control surfaces, and radomes due to their high strength-to-weight ratio. Additionally the marine industry benefits from their corrosion resistance, employing them in boat hulls, decks, and interior fittings. Moreover, fiberglass panels play a significant role in the renewable energy industry, particularly in wind energy, where they form the structural elements of wind turbine blades, harnessing the power of the wind efficiently.

The Future of Fiberglass Panels

The future of fiberglass panels appears bright, with ongoing advancements and innovations driving their growth and application. To start, manufacturers are refining production processes to make them more efficient, cost-effective, and environmentally friendly. Additionally, efforts to develop eco-friendly resins and incorporate recycled materials are being introduced to reduce their environmental impact. Furthermore, research is focusing on enhancing strength, durability, and structural capabilities by exploring advanced reinforcement techniques and hybrid composites. Advanced surface finishes and customizable designs are also being explored to offer aesthetic appeal for architectural applications. Additionally, the integration of smart technologies and self-healing mechanisms are improving functionality and maintenance. As a result of these factors, the future holds expanded applications, improved performance, and a sustainable focus for fiberglass panels, likely resulting in fiberglass panels playing an integral part of various industries and technological advancements.

Choosing the Proper Fiberglass Panel Manufacturer

To ensure you have the most constructive outcome when purchasing fiberglass panels from a fiberglass panel manufacturer, it is important to compare several companies using our directory of fiberglass panel manufacturers. Each fiberglass panel manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each fiberglass panel business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple fiberglass panel companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services