Fiberglass, which is also the term commonly used for fiberglass reinforced plastic, has many benefits when compared to alternatives like aluminum and wood. The thin fibers of glass that form the reinforcing cloth are actually stronger than steel and much lighter. It also resists rust and erosion much better than aluminum. In aquatic applications like boat hulls, fiberglass resin lasts much longer than wood, which deteriorates quickly when wet. It won’t scratch and is chemically resistant, making it a popular material for go-cart and racecar shells, storage tanks and automotive parts.

Once the molten glass has been extruded into fine threads, they are either woven into mats and fabric, or spun into wool. To make wool out of glass, the glass is pushed through a rapidly spinning container. When they are pushed through little holes, a hot gust of air or gas converts the threads into fibers. The fibers are interlaced with each other, resulting in a mound of fleecy material. When molding fiberglass, the process differs a bit after the glass fibers are made. Instead of wool, they are woven into a fabric-like mat or chopped into shorter pieces. Various protective coatings and plastic resin layers are added to the glass cloth and then molded into a specific shape. The fiberglass resin material is also sometimes applied onto other materials to create an airtight and protective layer.

Fiberglass Fabricators

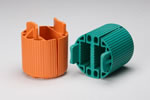

Fiberglass Fabricators Injection Molded Plastics

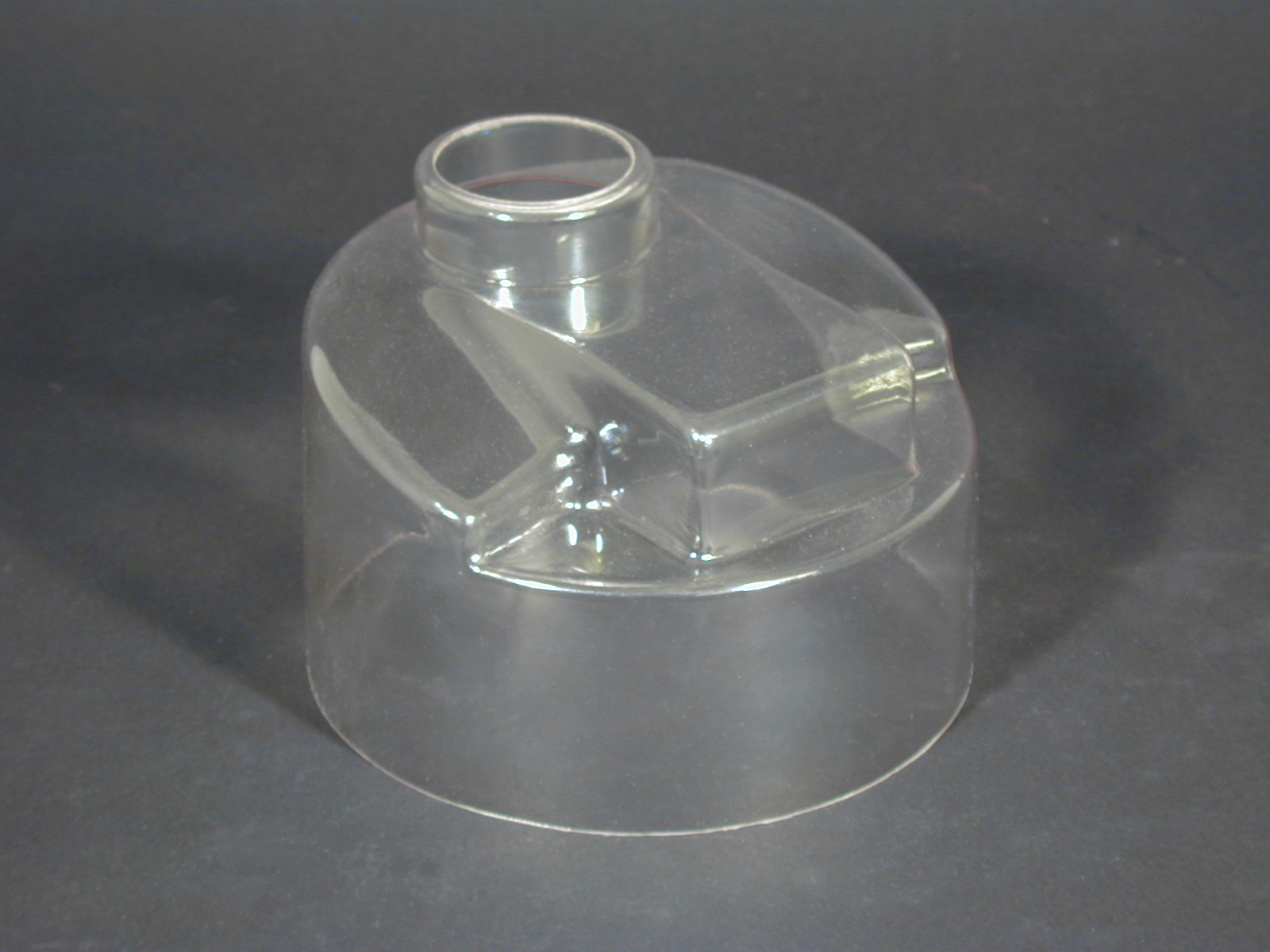

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services